DAC Worldwide

DAC Worldwide, a US-based world leader in technical training solutions has been helping maintenance departments, training professionals, vocational educators, and workforce development specialists with realistic, hands-on training systems for over 35 years.

DAC Worldwide has a wide range of products to help you build custom courses to meet your industrial training needs. The cutaways provide a better understanding of how components actually work, which is great for teaching both fundamentals and troubleshooting. The dissectibles teach essential hands-on skills for disassembly and assembly. Finally, the models allow you to explain how the various components of a system work together to create an entire process.

-

Proven Oil & Gas TrainingItem Number:295-713DAC Worldwide’s Pneumatic Level Controller Assembly Cutaway (295-713) is a sectioned, highlighted float-operated pneumatic level controller assembly that allows for realistic demonstration and training related to this common level control device used in oil and gas production operations.

-

Oil Production Training AidItem Number:295-722DAC Worldwide's Pneumatic Level Switch Cutaway, Oilfield-Type (295-722) is a realistic, sectioned example of a common industrial level switch, as used in oilfield production applications and other process systems.

-

Real-World Petroleum Equipment & Components for Maintenance TrainingItem Number:295-719PDAC Worldwide’s Pneumatic Surface Safety Valve Cutaway (295-719P) depicts a sectioned full-size valve sample. A key component in ESD systems, these safety-related wellhead components ensure system shutdown in emergency circumstances.

-

Hands-On Process Control SkillsItem Number:616-000DAC’s Portable Calibration Training System (616-000) is a portable tabletop instrument calibration workstation that allows for convenient testing and calibration of instruments, process controllers, and other instrumentation and process control-related components.

-

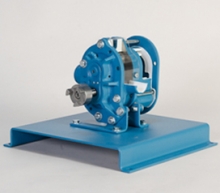

Basic Mechanical Valve CutawayItem Number:211-140DAC Worldwide’s Positive Displacement Blower Cutaway, Rotary Lobe-Type (211-140) is a full-size, fully-detailed sectioned rotary lobe-type positive displacement compressor that provides learners a first-hand view into a component that is found in various applications worldwide.

-

Hands-On Technical Trainer for Industrial Maintenance TechniciansItem Number:211-110DAC Worldwide’s Positive Displacement Compressor Cutaway, Piston-Type (211-110) is a realistic, sectioned, piston-type positive displacement compressor. Rather than a scale model, the cutaway is a piece of actual industrial hardware sourced from popular industrial makes and models. T

-

Hands-On Skill TrainingItem Number:272-980DAC Worldwide's Pressure Control Switch Sample Dissectible (272-980) is a realistic dissectible sample of a common industrial control-type pressure switch as used in automation and process systems.

-

Teach Disassembly, Assembly, & Inspections SkillsDAC Worldwide's Pressure Switch Sample Dissectible (272-981) is a realistic dissectible sample of a common industrial pressure switch.

-

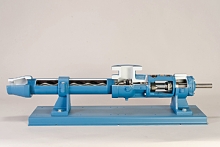

Hands-On Industrial TrainingItem Number:278-195DAC Worldwide’s Progressive Cavity Pump Cutaway – Moyno/Roper (278-195) depicts a sectioned industrial progressing cavity pump that allows for convenient classroom or laboratory training in the operating characteristics, construction, and maintenance of these common process pumps used in a variety of sectors.

-

A standard-size, floor-standing unit that provides an in-depth, hands-on understanding of the basic, practical, and theoretical elements of the liquid-liquid extraction process.Item Number:ELL/4000The unit is used manually, with flows controlled by manual valves and flowmeters. The unit has a 2"-diameter glass column, which enhances the visual experience of the extraction process. A pneumatic pulsator increases the contact between the two phases and mass transfer. Students learn how to determine the interphase level, material balance, efficiency of the column, and more.