This video will guide you through getting your CarTrain ready for use. Daniel and Christian will start with the unboxing of the different crates and then show you how to assemble the table and prepare the CarTrain for the first use. Later in the video, you will learn how to use the trainer together with the eLearning software Labsoft. You will run through some practical tasks as well as the whole shutdown process of the high voltage system. Finally, there will be a deep dive into the diagnostic tasks of the CarTrain using the example of an insulation fault.

What is LIFT? One of only a handful of Manufacturing USA Institutes across the country, LIFT is a nonprofit, public-private partnership between industry, academia, and government that supports the nation’s economy and enhances its national security by accelerating innovative advanced manufacturing technology and talent development.

In this video, STEM Talent Program Manager Bernie Simms, Learning Lab Manager Jihad Mims, and Learning Lab/Robotics Instructor Isaac Vanover discuss LIFT’s unique mission to research and develop innovative lightweight materials that advance the nation’s military defense and manufacturing capabilities.

According to Mims, “We also realized that there’s a very large skills gap. Over 2.5 million jobs within manufacturing were going unfilled, so to bridge that gap, we also wanted to make sure that education and workforce development was implemented in LIFT’s atmosphere. ”

That’s why you’ll find a wide variety of Amatrol training systems and eLearning curriculum in the LIFT Learning Lab. Amatrol also partnered with LIFT to develop the IGNITE: Mastering Manufacturing high school career and technical education program.

A fully automated cartoner for pouches, featuring robotic collation and loading, was engineered by FANUC’s Authorized System Integrator.

System Operation

Pouches emerge from the customer's pouch form-fill-seal (FFS) machine in a single-file fashion. The M-1iA robot strategically arranges alternate pouches, forming dual lanes at the cartoner infeed. Subsequently, two M-2iA robots precisely stage the pouches within collation fixtures, while an SR-6iA erects auto-bottom cartons and positions them on the carton conveyor. An M-10iD/12 robot expertly picks the staged pouches and deposits them into the erected cartons. The carton's top is then folded and tucked, and a collaborative CRX-10iA robot efficiently removes closed cartons, transferring them onto racks.

Key Advantages

- Capable of handling 100 pouches per minute

- Enhanced packaging speed

- Reduced footprint

ESS Technologies, Inc., a Pacteon Company, is a leading expert in comprehensive packaging line solutions, catering to industries such as pharmaceuticals, nutraceuticals, cosmetics, and consumer packaged goods. With a foundation dating back to 1993, ESS possesses extensive proficiency in designing, manufacturing, and integrating automatic cartoners, case packers, robotic palletizers, and TaskMate Robotic Systems®.

This video is part of a video collection showing the start-up and operation of the training system.

Trainees work directly on a real high-voltage system, which has been adapted with special safety features to be used without any prior qualifications. Thus, this training system provides a safe work environment and allows students and trainees to focus on the task entirely. The content is based on worldwide curriculums (ASE L3 and DGUV 200-005).

Trainees can become familiar with all the key theoretical backgrounds by utilizing an interactive e-learning course. Each theoretical section is accompanied by practical exercises and tests of knowledge, which also help advance vital diagnostic skills. These skills are further boosted by the built-in diagnostic system and the scrupulously selected fault scenarios.

This is the only training system that allows students to develop various diagnostic strategies involving measurements on an actual HV system with real HV voltages under the most stringent safety conditions.

This video is part of a comprehensive collection showcasing the setup and operation of our training system.

Trainees engage directly with a genuine high-voltage system, meticulously equipped with specialized safety features, enabling safe utilization without prior qualifications. This ensures a secure learning environment, allowing students and trainees to concentrate fully on their tasks. This content aligns with global curriculums, such as ASE L3 and DGUV 200-005, ensuring relevance and applicability.

Through interactive e-learning modules, trainees delve into the essential theoretical foundations. Each theoretical segment is complemented by practical exercises and knowledge assessments, enhancing diagnostic skills crucial for success. Supported by a built-in diagnostic system and carefully selected fault scenarios, trainees develop proficiency in diagnostic strategies.

This training system stands out as the sole platform offering students the opportunity to employ various diagnostic techniques, including measurements on authentic HV systems with real HV voltages, all within the strictest safety parameters.

As a distributor, we're pleased to present a video from our collection showcasing the setup and operation of our training system.

Trainees engage directly with an authentic high-voltage system, equipped with specialized safety features for safe usage without prior qualifications. This ensures a secure learning environment, enabling students and trainees to concentrate fully on their tasks. Our content is aligned with global curriculums, including ASE L3 and DGUV 200-005, ensuring relevance and adherence to industry standards.

Through interactive e-learning courses, trainees delve into key theoretical concepts. Each theoretical module is complemented by practical exercises and knowledge assessments, fostering the development of vital diagnostic skills. Supported by a built-in diagnostic system and carefully selected fault scenarios, trainees further enhance their diagnostic proficiency.

This training system stands apart as the sole platform offering students the opportunity to develop various diagnostic strategies, including measurements on an actual HV system with real HV voltages, all within the strictest safety parameters.

In this informative tutorial video, discover the ins and outs of navigating the touch screen interface on the CarTrain CO3221-6X. Whether you're a novice or an experienced user, this step-by-step guide will walk you through the various functions and features of the touch screen, allowing you to optimize your training experience. From accessing different modules to adjusting settings, learn how to harness the full potential of the touch screen interface with ease. Mastering this essential skill will enhance your proficiency in operating the CarTrain CO3221-6X and unlock a world of possibilities in automotive training.

Unlock the full potential of your CarTrain CO3221-6X with our comprehensive tutorial on "Ready Mode." In this step-by-step guide, you'll learn how to activate and utilize the Ready Mode feature effectively. Whether you're preparing for a training session or optimizing system performance, mastering Ready Mode is essential for maximizing efficiency and productivity. Join us as we explore the ins and outs of this essential feature, empowering you to take your automotive training to the next level.

Dive into the intricacies of configuring the High Voltage System on your CarTrain CO3221-6X with our comprehensive tutorial. In this step-by-step guide, we'll walk you through the process of setting up the High Voltage System, ensuring safety and efficiency every step of the way. Whether you're a novice or an experienced user, this video will equip you with the knowledge and skills needed to navigate the setup process seamlessly. Join us as we explore the key components, safety protocols, and best practices for configuring the High Voltage System, empowering you to make the most of your CarTrain CO3221-6X and elevate your automotive training experience.

Embark on your journey with the CarTrain CO3221-6X by mastering the essentials in our comprehensive tutorial, "Getting Started." Whether you are a newcomer or a seasoned user, this step-by-step guide will walk you through the initial setup and configuration process, ensuring a smooth and efficient start to your training experience. From powering the system to navigating the interface, you'll learn everything you need to know to confidently hit the ground running. Join us as we explore the foundational steps of using the CarTrain CO3221-6X, empowering you to unlock its full potential and elevate your automotive training to new heights.

Pages

-

Item Number:421-000DAC Worldwide’s 1-Phase Motor Control Training System with Magnetic Starter (421-000) is a motor control-related device for training in the operational principles, wiring, fault troubleshooting, and application of industrial single-phase, magnetic motor starters.

-

Item Number:420-000DAC Worldwide’s 1-Phase Motor Control Training System with Manual Starter (420-000) is a motor control-related device for training in the operational principles, wiring, fault troubleshooting, and application of industrial single-phase, manual (across the line) starters.

-

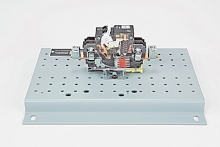

Item Number:273-907DAC Worldwide’s 100A, Single Pole Circuit Breaker Cutaway (273-907) is a detailed and professionally-crafted circuit breaker cutaway that depicts a common DIN-rail-mounted, single-phase industrial breaker. T

-

Item Number:2FG7OnRobot's 2FG7 Finger Gripper is a complete, low-cost, off-the-shelf electric parallel gripper that can be deployed on any major collaborative or light industrial robot within minutes and requires no custom engineering for installation, programming, or maintenance.

-

Item Number:2FGP20The OnRobot 2FGP20 electric gripper offers a wide stroke and customizable arms to easily handle containers that can’t be handled with traditional vacuum grippers. Like all OnRobot electric grippers, the 2FGP20 provides fast, out-of-the-box deployment with intuitive programming.

-

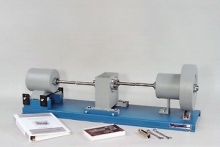

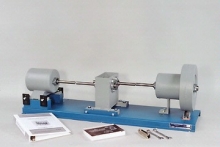

Item Number:206-000Basic mechanical maintenance skills are fundamental throughout advanced manufacturing and a wide variety of industries. For example, industrial maintenance technicians must possess essential knowledge and skills to perform shaft alignments and maintain, troubleshoot, and repair a variety of couplings.

-

Item Number:206-PACBasic mechanical maintenance skills are fundamental throughout advanced manufacturing and a wide variety of industries. For example, industrial maintenance technicians must possess essential knowledge and skills to perform shaft alignments and maintain, troubleshoot, and repair a variety of couplings.

-

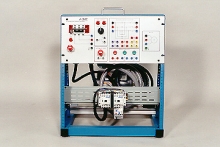

Item Number:423-000DAC Worlwide’s 3-Phase Motor Control Training System with Magnetic Starter (423-000) is a motor control-related device for training in the operational principles, wiring, fault troubleshooting, and application of industrial three-phase, reversing magnetic starters.

-

Item Number:424-000DAC Worldwide’s 3-Phase Motor Control Training System with Magnetic Starter, Low Voltage Start (424-000) is a motor control-related device for training in the operational principles, wiring, fault troubleshooting, and application of industrial three-phase, reversing magnetic starters.

-

Item Number:422-000DAC Worldwide’s 3-Phase Motor Control Training System with Manual Starter (422-000) is a task-specific, motor control-related training device that allows for skill-building in the operational principles, circuit design, wiring, fault troubleshooting, and application of industrial three-phase, manual motor starters.