Amatrol’s PLC Troubleshooting Learning System - AB ControlLogix (890-AB5500) teaches troubleshooting, programming, and applications of Allen-Bradley’s ControlLogix PLC. The programmable controller is considered by many to be the most important development ever in industrial automation, because it is a prepackaged, industrially-hardened computer that can be quickly programmed to control a wide range of industrial processes and machines. The A-B ControlLogix training system adds to the Programmable Controller Troubleshooting Workstation (890-PECB) and also requires a computer and RS Logix 5000 PLC programming software.

The A-B ControlLogix training system includes an Allen-Bradley PLC with ControlLogix 5000 processor, an I/O Connector Kit, and a Fault Insertion Engineering Integration and Connector Kit. These components will be used to cover a wide variety of PLC topics, applications, and skills, such as PLC operation, communications, programming, motor control, I/O interfacing, timer and counter instructions, and systems and I/O troubleshooting. The ControlLogix 5000 is a PLC that learners will actually find in automated manufacturing facilities and other industrial settings, so the skills and knowledge that they gain from the A-B ControlLogix training system will be directly applicable to real-world environments.

Amatrol’s Programmable Controller Troubleshooting Workstation (890-PECB) teaches programming and troubleshooting of programmable logic controllers (PLCs) and their use in industrial, commercial, and residential applications. The PLC Troubleshooting Workstation teaches PLC troubleshooting like no other product by providing a hands-on learning station that models real world PLC-controlled machines with up to 40 faults that can be inserted into the system. It’s the first product to offer a realistic PLC troubleshooting experience for students, because the faults are inserted throughout the system, including inside the PLC!

Hands-On Maintenance & Troubleshooting Skills

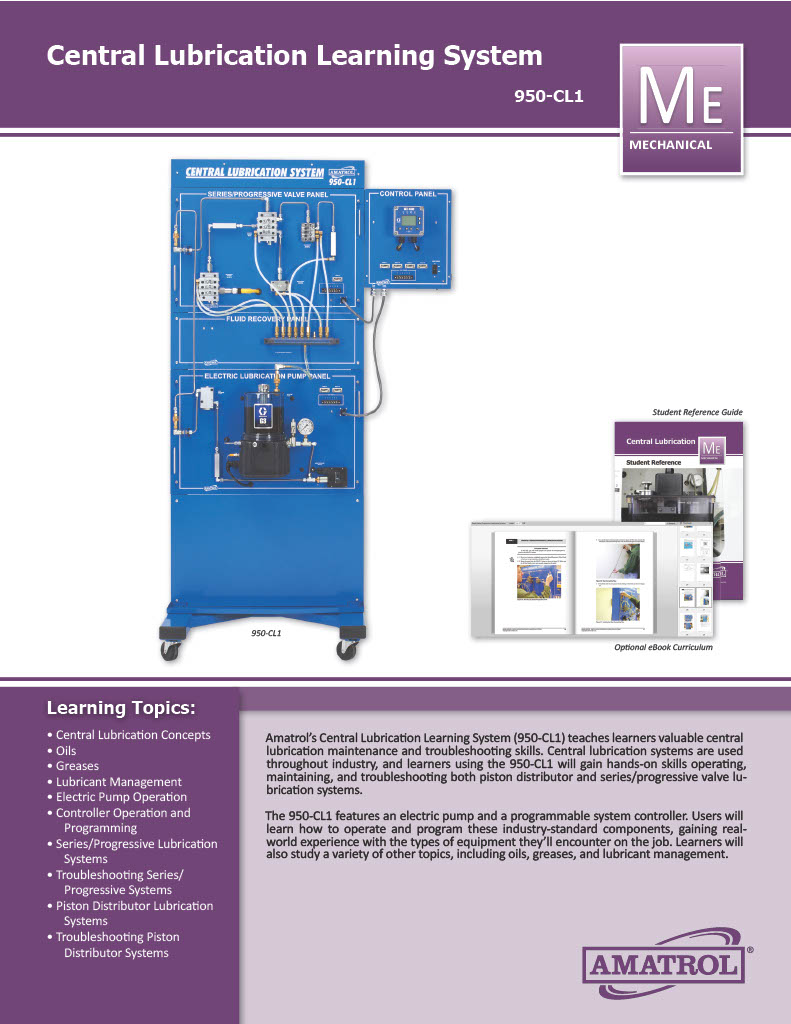

Amatrol’s Central Lubrication Learning System (950-CL1) teaches learners valuable central lubrication maintenance and troubleshooting skills. Central lubrication systems are used throughout industry, and learners using the central lubrication training system will gain hands-on skills operating, maintaining, and troubleshooting both piston distributor and series/progressive valve lubrication systems.

The central lubrication training system features an electric pump and a programmable system controller. Users will learn how to operate and program these industry-standard components, gaining real-world experience with the types of equipment they’ll encounter on the job. Learners will also study a variety of other topics, including oils, greases, and lubricant management.

Amatrol’s 950-GEO2D Geothermal Troubleshooting Learning System with Desuperheater uses an exposed component layout so that learners can see each component’s role in a geothermal system. Learners can easily observe, monitor, and test each component mounted and labeled on a vertical panel. Sight glasses installed in the 950-GEO2 allow the learner to see the refrigerant’s changing state as it passes through the system. Amatrol also includes pressure and temperature gauges at key points to show the system’s performance at a glance. Additionally, the system includes a custom designed, temperature-controlled ground simulator so the system can run continuously.

The 950-GEO2D is equipped with FaultPro, Amatrol’s premier electronic fault insertion program for teaching troubleshooting skills. Using FaultPro, learners troubleshoot electrical, mechanical, and fluid-based faults to become effective real-world experts on residential and commercial geothermal systems. In addition to troubleshooting, the interactive multimedia curriculum and hands-on skills will teach startup, operation, shutdown, and maintenance of a geothermal system.

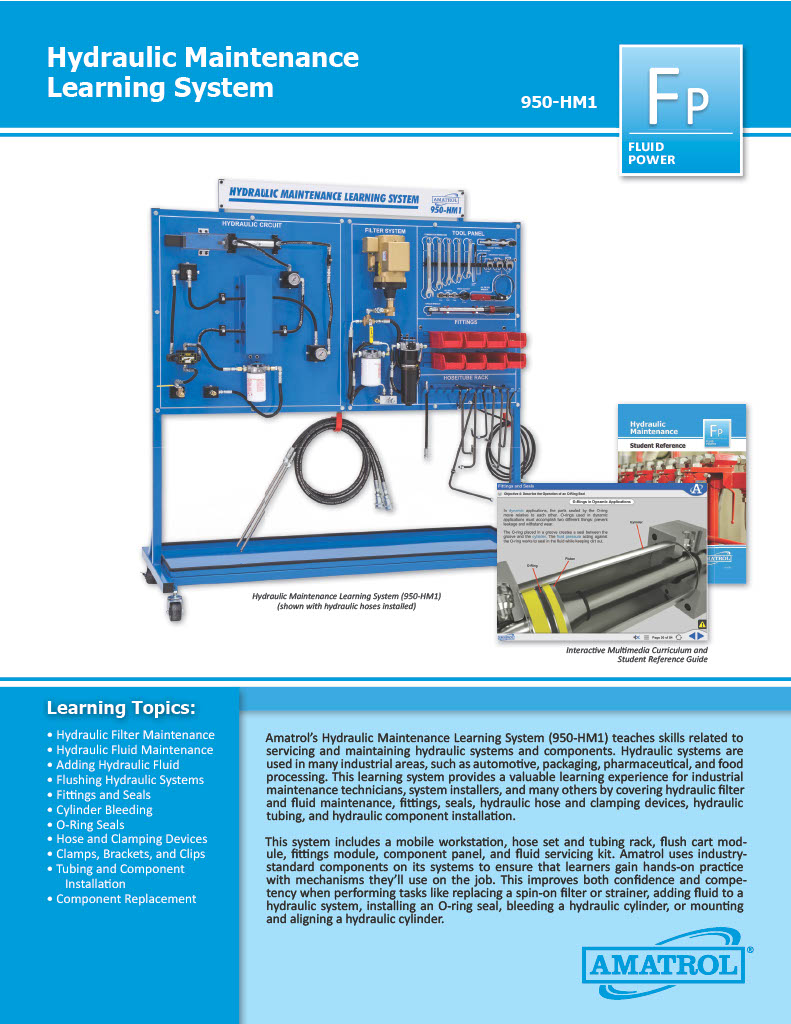

Amatrol’s Hydraulic Maintenance Learning System (950-HM1) teaches skills related to servicing and maintaining hydraulic systems and components. Hydraulic systems are used in innumerable industrial areas like automotive, packaging, pharmaceutical, and food processing. This learning system provides a valuable learning experience for industrial maintenance technicians, system installers, and many others by covering hydraulic filter and fluid maintenance, fittings, seals, hydraulic hose and clamping devices, hydraulic tubing, and hydraulic component installation.

This system includes a mobile workstation, hose set and tubing rack, flush cart module, fittings module, component panel, and fluid servicing kit. Amatrol uses industry-standard components on its systems to ensure that learners gain hands-on practice with mechanisms they’ll use on-the-job. This improves both confidence and competency when performing tasks like replacing a spin-on filter or strainer, adding fluid to a hydraulic system, installing an O-ring seal, bleeding a hydraulic cylinder, or mounting and aligning a hydraulic cylinder.

Amatrol’s Hydraulic Troubleshooting Learning System (950-HT1) teaches advanced hydraulic troubleshooting like no other product by providing a hands-on learning station that models a real world hydraulically-powered machine and includes over 40 faults that can be inserted into the system. The 950-HT1 is the first product to offer a realistic electrical component troubleshooting experience for students, because the faults are inserted throughout the system, including the hydraulic, mechanical and electrical components.

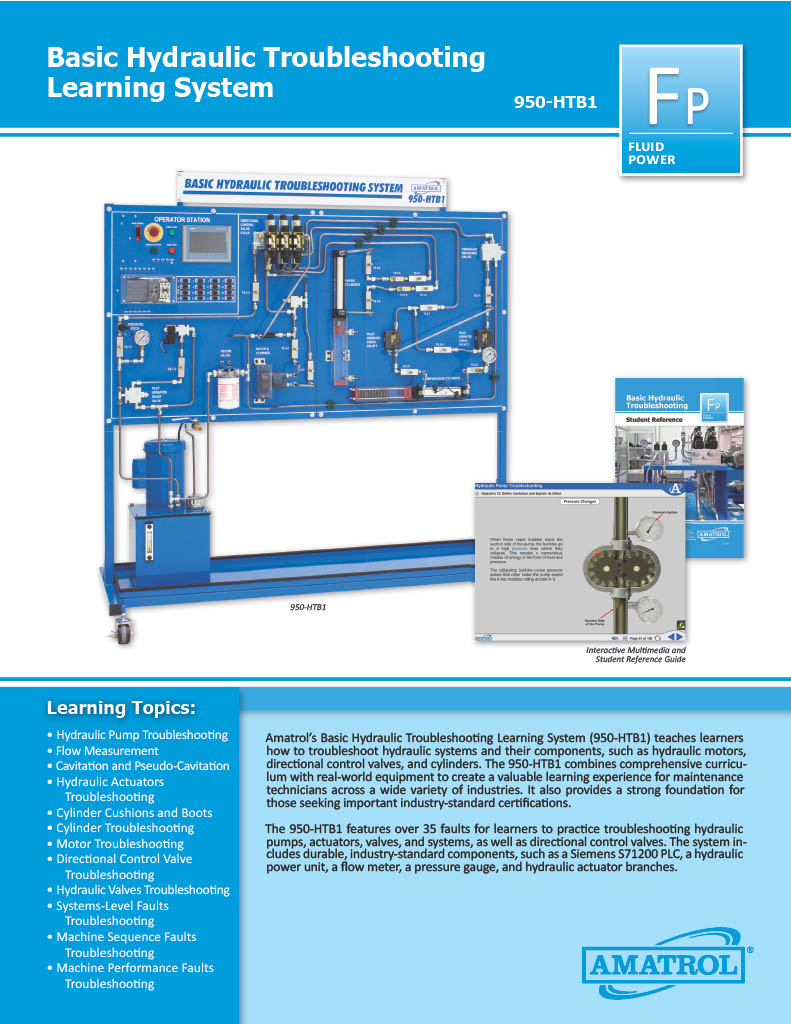

Amatrol’s Basic Hydraulic Troubleshooting Learning System (950-HTB1) teaches learners how to troubleshoot hydraulic systems and their components, such as hydraulic motors, directional control valves, and cylinders. The system combines comprehensive curriculum with real-world equipment to create a valuable learning experience for maintenance technicians across a wide variety of industries. It also provides a strong foundation for those seeking important industry-standard certifications.

The hydraulic troubleshooting system features over 35 manually-inserted faults to help learners understand and practice troubleshooting common problems found in hydraulic systems. Sample faults include: motor starter failure, defective pump, worn cylinder seals, blocked flow control valves, and blocked inlet ports.

Amatrol's Mechanical Fabrication Learning System (950-MPF1) covers industry-relevant mechanical fabrication skills from basic to more sophisticated power tools, including skills ranging from using c-clamps, vises, and pliers, to more advanced torque tools, torque wrenches, and power tools. Students learn about the many types of bolts, wrenches and other fittings commonly used in industry and how to properly apply them. This includes pneumatic fabrication fittings. Testing fittings with air and a liquid soap solution determines if a pressure type seal has been made. This technique is often used in industry because there is too much noise on the plant floor to hear a leak and determine its precise location.

Print Reading is a foundational skill use throughout many industries. Amatrol’s Print Reading eLearning Courseware (M12207) covers topics like print dimensioning, assembly drawings and fasteners, and geometric dimensioning & tolerancing (GD&T). Learners using Amatrol’s print reading training course will study sketching, multiview drawings, dimensioning rules, first-angle projection, holes and fasteners, assembly drawings, assembly tolerances, and feature control frames. From this building block, learners can practice industry-relevant skills like selecting the appropriate number of views for an object, interpreting information blocks on a print, and calculating the limits of a dimension given its tolerance.

Amatrol's Piping Learning System (950-PS1) teaches learners how to lay out and assemble a fluid piping system used in industrial, construction, agricultural, and transportation applications. Students will learn how to select, size, identify, and install a variety of types of industrial fluid piping, fittings and valves including: iron pipe, steel tubing, hydraulic hose, plastic pipe, copper tubing, globe valves, gate valves, check valves, and Sloan valves.

The fluid piping trainer includes a mobile workstation, pump testing network, valve package, fitting package, fitting identification kits, Sloan valve maintenance kit, pipe insulation and hanger components, fitting storage, student learning materials for both theory and lab, and teacher’s guide. The workstation has slotted, movable members to enable a variety of hydraulic hose fluid piping application scenarios to be set up.

Pages

-

Item Number:373-602This economical, sectioned example showcases the device’s operating principle, internal components, and related installation concerns. Multiple cutaways unveil all internal components, which enhances classroom training in HVAC system design, maintenance, troubleshooting, and preventive/predictive maintenance.

-

Item Number:373-510This sectioned example showcases the device’s operating principle, internal components, and related installation concerns. Color coding, flow arrows, and numbered call-outs combine to make the device more informative to the inquiring student and more useful to the instructor.

-

Item Number:373-551This ACR Manual Balancing Valve Cutaway provides a full cutaway view of a balancing valve that exposes the complete internal components and operating principles. The device can be used independently using an optional tabletop mounting foot, or combined with similar devices on optional display and storage frame assemblies.

-

Item Number:373-721This ACR Oil Separator Cutaway, Float-Type provides a full cutaway view of an oil separator that exposes the complete internal components and operating principles. Color coding, flow arrows, and numbered call-outs combine to make the device more informative to the inquiring student and more useful to the instructor.

-

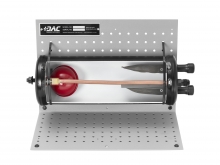

Item Number:373-722DAC Worldwide’s ACR Oil Separator Cutaway, Helical-Type is a professionally-crafted, economical teaching aid that depicts a conventional helical-type centrifugal oil separator commonly used in industrial and commercial refrigeration systems for oil entrapment and compressor crankcase replenishment.

-

Item Number:373-503This ACR Packless Diaphragm Line Valve Cutaway provides a full cutaway view of the diaphragm line valve that exposes the complete internal components and operating principles.

-

Item Number:373-502DAC Worldwide’s ACR Solenoid Valve Cutaway is a sectioned example of a commonly-encountered solenoid valve used in air conditioning and refrigeration systems with a remotely-operated maintenance-related block valve, system fluid, or gas flow control valve.

-

Item Number:373-501This ACR Steel Ball Valve Cutaway provides a full cutaway view of the compressor body that exposes the complete internal components and operating principles. Economically mounted on a formed-steel and powder-coated modular display panel, this sample panel can be mounted on a variety of optional benchtop display fixtures and storage structures.

-

Item Number:373-506This ACR Straight-Thru Pressure Relief Valve Cutaway provides a full cutaway view of the reversing valve that exposes the complete internal components and operating principles.

-

Item Number:373-701This ACR Suction Line Accumulator Cutaway provides a full cutaway view of an accumulator that exposes the complete internal components and operating principles. Color coding, flow arrows, and numbered call-outs combine to make the device more informative to the inquiring student and more useful to the instructor.