The full-color, multi-material Stratasys® J850™ TechStyle™ and J850™ Prime FabriX™ printers powered by 3DFashion™ technology boast the innovative capability of printing 3D designs directly onto fabric. With Stratasys printing materials, combinations of colors, transparency, and flexibility are possible all in one print on different textiles and flexible substrates.

The full-color, multi-material Stratasys® J850™ TechStyle™ and J850™ Prime FabriX™ printers powered by 3DFashion™ technology boast the innovative capability of printing 3D designs directly onto fabric. With Stratasys printing materials, combinations of colors, transparency, and flexibility are possible all in one print on different textiles and flexible substrates.

The following sections describe tips, guidelines, and online resources for designers to start 3D printing using Stratasys technologies and materials. With this wealth of information and your experimentation, you will gain the knowledge and skills you need to achieve outstanding results.

Guidelines and Tips

- Tips for Getting Started

- Vector Designs

- Distance Between Elements

- Element Size

- Element Height

- Size Recommendations Table

- Color Assignment

- File Type Support

- Stratasys Online Resources

Printer performance and reliability directly impact your bottom line. Stratasys' F123 line of FDM 3D printers is the most accurate compared to various competitors and the fastest, with the least downtime. Confidently print more parts in less time with a Stratasys F123 series FDM 3D printer.

Industry Report: White Paper

Desktop and low-priced 3D printers may seem the logical choice to start with 3D printing. But it’s often the wrong choice because these 3D printers are typically not up to the task nor have the trusted reliability of FDM technology.

This white paper highlights a third-party head-to-head comparison and how each 3D printer fared. Curious to know how F123 Series FDM 3D printers stack up against these competitors?

Download this white paper, evaluate and learn how F123 Series out preforms it's competition.

PPSF/PPSU (polyphenylsulfone) material has the greatest heat and chemical resistance of all Fortus® materials - ideal for aerospace, automotive and medical applications. PPSF parts manufactured on Fortus 3D Printers are not only mechanically superior, but also dimensionally accurate, to better predict end-product performance. Users can also sterilize PPSF via steam autoclave, EtO sterilization, plasma sterilization, chemical sterilization and radiation*. PPSF gives you the ability to manufacture parts direct from digital files that are ideal for conceptual modeling, functional prototyping, manufacturing tools and production parts.

PPSF (polyphenylsulfone) is a high-temperature, high-strength, and chemically resistant FDM material. While ideal for demanding applications, the durability and chemical resistance make finishing PPSF parts with sandpaper or solvents difficult and time-consuming.

When smooth surfaces are needed, hand sanding or milling are the two options most often used. Resistant to abrasion, PPSF makes hand sanding a laborious task that can consume hours. While a finishing pass with a CNC mill can make short work of surface smoothing, it negates many of the advantages of the FDM process. To prepare for machining, time is needed for CAM programming and machine set-ups. Machining also requires that an operator oversees the process.

If PPSF is used to make tools or molds, there is a new and faster alternative for surface smoothing, thermoforming. A thin sheet of plastic is drawn onto the surface of the PPSF part. While it conforms to the part’s shape, the plastic sheet does not transfer the layer lines to the outer surface. To preserve the mechanical, thermal, and chemical advantages of PPSF, the thermoforming process uses sheets of plastic made from PEEK resin. Versus hand sanding, PEEK thermoforming can reduce lead time by 75 percent

and cost by 90 percent (table 1).

More reliable, more affordable, more productive rapid prototyping and manufacturing than ever before.

Stratasys' F123 Series 3D printers give designers, engineers, and educators access to affordable, industrial-grade 3D printing. Work faster through concept iterations and component verification. Make jigs, fixtures, and manufacturing tools faster, with strong, stiff materials. Increase productivity and reach your goals sooner with repeatable results.

30 years of expertise. One leader in FDM.

For manufacturers new to 3D printing and established factory floors alike, Stratasys FDM® 3D printers are the game-changing choice — allowing you to build strong, durable, and dimensionally stable prototypes, tools and production parts with industry-leading repeatability and reliability. Additionally, our experts are well-versed in many global manufacturing methods and ready to help you find ways to shave days off production cycles, meet industry demands and maximize throughput.

Make it with GrabCAD

GrabCAD Print™ simplifies the traditional 3D print preparation workflow and provides intelligence around printer technology so your team can get quality prints, faster.

GrabCAD Print Pro™ takes GrabCAD Print to the next level. It reduces the number of prints required to meet a design’s intent. It simplifies process definition and estimation, integrates to partner software and other systems, and automates tasks to optimize workflows.

Together, GrabCAD Print and GrabCAD Print Pro are the ideal solutions for your production and prototyping needs.

Expanding Applied Learning

Students Gain High-Demand Skills with 3D Printing

Dunwoody College of Technology (Dunwoody) was founded in Minneapolis, Minnesota, in 1914 to provide a rigorous, industry-focused technical education. As the region's oldest and only non-profit technical college, Dunwoody has garnered an international reputation for its successful approach.

Dunwoody incorporates hands-on, applied learning with 3D printing playing a crucial part in the curriculum. Students learn critical thinking and practical, real-world skills in high demand. “In the last three years, there has been a huge momentum increase in 3D printing at Dunwoody, and students want programs centered on it,” said E.J. Daigle, Dean of Robotics & Manufacturing at Dunwoody."

Complex Designs Fast

Deisgn Firm 3D Prints to Refine Ideas with Speed

At the Center for Advanced Design (CAD), a product development firm in Minnesota, USA, a team of design engineers specializes in creating complex surface geometry for the plastics industry. The agile team of six handles everything from industrial design concepts and digital sketching to assisting clients with implementation by building production tooling. Their ability to advance projects quickly keeps their specialized team very busy.

“We’ve carved a niche out for ourselves designing plastic components for customers in the power sports industry,” Jesse Hahne, partner at CAD, said. “Many of the larger companies we work for are very talented, but they move slower. When deadlines loom, they look to us to get their complex projects back on track.”

These tips and tricks are designed to help you create better and more stable parts using PLA materials on any of the Stratasys F123™ Series 3D Printer.

Pages

-

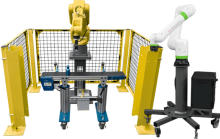

Item Number:AD2446-20The ClassMate® M cell is a complete robotic training solution designed to meet the need for advanced manufacturing training. Instructors can teach robotic concepts in the classroom and quickly move to the lab for welding practice.

-

DAC Worldwide’s selection of furniture offers a variety of solutions for creating flexible and functional training areas. Designed to work with DAC Worldwide's training systems, cutaways, models, and dissectibles, available furniture options allow you to create workstations, displays, or storage areas.

-

GrabCAD Print is a complete solution for Stratasys 3D printers. The intuitive, easy-to-use software simplifies preparing, scheduling, monitoring, and reporting print jobs. With the ability to read and understand CAD files natively, GrabCAD Print offers an efficient workflow that streamlines job management.

-

Item Number:400-PAC

DAC Worldwide’s Basic Electricity Training System Plus (400-PAC) examines basic AC and DC electrical principles. Learners will explore how electricity is used for power and control in various sectors, including industrial, commercial and residential applications. The training covers industry-relevant skills, such as installing, operating, and troubleshooting AC and DC electrical circuits in a variety of applications.

-

Safety fencing, conveyors, robot pedal stools, and CRX mobile carts