Amatrol’s Portable Electric Motor Control Troubleshooting Learning System (990-MC1FSL) features standard industry components like a 3-phase AC squirrel cage motor and uses 3-phase AC for power and 24 VDC for control all packed within a space-saving, portable product. These real-world motor control components will prepare learners for work opportunities in industries where electric relay control is used in applications like conveyor control and driving large utility pumps. Teach students how to read and interpret ladder diagrams. The 990-MC1FSL also uses FaultPro, Amatrol’s unique electronic fault insertion, to teach motor control troubleshooting skills, such as control relay, reversing contactor, limit switch, and pushbutton troubleshooting.

The 990-MC1FSL uses industrial components to cover the operation, installation, and applications for electric relay control of AC motors all within this portable, durable learning system that can be set up nearly anywhere. This system also builds knowledge and skills across topics like manual motor control, control ladder logic, motor starters, and automatic input devices. Nowhere else can you find this breadth of training in a portable platform!

Amatrol’s Portable Mechanical Drives 1 Learning System (990-ME1M) covers the fundamentals of mechanical transmission systems and applications, such as how to: operate, install, analyze performance, and design basic mechanical transmission systems using chains, vbelts, spur gears, bearings, and couplings. These mechanical system fundamentals can be applied to a variety of applications within the automotive, agricultural, and power industries.

The 990-ME1M includes: a tabletop mounting work surface; a drive motor; a variety of components for belt, chain and gear drives; a digital tachometer; a mechanical load device; and an alignment package. This power transmission training system uses industrial quality components to help assure that learners are better prepared for what they will encounter on the job and to withstand frequent use. These components will be used to cover major mechanical drives topics like shaft speed measurement, key fasteners, power transmission systems, belt drive concepts, chain tensioning, and gear backlash. The 990-ME1M features the ability to set up various drive systems, showing learners the effects of proper alignment and how to obtain best efficiency.

Amatrol’s Portable Fundamental Measurement Tools Learning System (990-MES1) introduces the fundamental principles of measurement including basic measurement, precision measurement, direct gauging, indirect gauging, and dimensional measurements using both the U.S. customary system as well as S.I. metric system. Understanding how to perform accurate measurements is relevant to technical careers such as quality control inspector, machinist, manufacturing engineer, operations manager, and production technician. The measurement training system’s compact size and durable case also provide for safe storage when available training space must be used to teach other topics.

The 990-MES1 allows learners to apply fundamental measurement principles using industry-standard tools like dial calipers, micrometers, and dial indicators to achieve accurate measurements that are essential to any technical career. Learners will acquire skills such as how to measure length, accurate measurement of inside and outside dimensions, measuring both in U.S. Customary and S.I. Metric units, and collecting measurement data. The 990-MES1 contains precisely-machined and numbered parts that challenge the learner to make accurate measurements. The measurement tools and parts were carefully selected to not only teach the learner how to use the tools properly, but to also teach them the proper application for their use.

Amatrol’s Portable PLC Troubleshooting Learning System - AB CompactLogix L16 (990-PAB53AF) teaches programmable logic controller (PLC) programming, operation, and applications used throughout industry. The system also utilizes FaultPro, the industry’s premier computer-based fault insertion system. FaultPro enables learners to develop key PLC troubleshooting skills, such as PLC input and output testing, software testing, and application troubleshooting.

This portable system provides hands-on experience with real-world components, including the powerful Allen-Bradley L16 CompactLogix 5300 PLC, a PanelView Plus terminal, an Ethernet Switch, an I/O Simulator, five application circuits, and a master control relay circuit. Learners will study industry-relevant applications and troubleshooting skills that will build a strong foundation for a successful career in a variety of industries.

Amatrol’s Portable PLC Troubleshooting Learning System - AB CompactLogix (990-PABCL1F) provides comprehensive PLC operation and troubleshooting knowledge in a portable format for when training space is constrained, but skill-building cannot be sacrificed! Learners will study topics like programmable controller operation, PLC Ethernet communication, basic PLC project elements, PLC motor control, event sequencing, and more!

Combining training in areas such as programming, motor control, and pneumatics, the 990-PABCL1F offers learners the chance to operate the powerful Allen-Bradley L16ER CompactLogix 5370 PLC, PanelView 800 HMI terminal, and networks throughout the curriculum to build PLC training skills. The PLC training system’s interactive multimedia curriculum offers an unmatched breadth and depth of knowledge and skill-building. Only Amatrol can provide this level of training using a compact, portable workstation.

Amatrol’s Portable Process Control (990-PC1) covers two of the most common types of process control systems, flow and liquid level, by providing eLearning curriculum and hands-on training for subjects like process control equipment safety, loop controllers, level measurement and control, control loop performance, and more!

In this video, Amatrol answers a familiar question from those unfamiliar with industry: "What is process control?" This video gives a basic definition of process control, how and where it's utilized in industrial application, and how we can help with your process control training needs.

The Portable Process Control Troubleshooting Learning System – Level & Flow (990-PC1F) from Amatrol provides a portable troubleshooting training system for flow and liquid level, two of the most common types of process control systems. The system features eLearning curriculum and hands-on training for subjects like process control equipment safety, loop controllers, level measurement and control, control loop performance, and more.

Amatrol's 990-PC1F portable trainer provides vital training experience for students and professionals that will perform operation, safety, and troubleshooting on process control systems used in real-world industrial areas, including power generation, petrochemicals, food processing and manufacturing. To teach real-world skills, the trianing system features industry-standard valves, switches, and gauges all within a portable basic process control learning system that can be placed on a conference room table, shop floor desk, or practically anywhere when training space is limited.

Process control systems, also known as process instrumentation systems, are used in power generation, petrochemicals, manufacturing, and other industries to provide precise control of liquids and gases. Amatrol’s Level and Flow Process Control Troubleshooting Learning System (T5552F) teaches calibration, installation, operation, and troubleshooting of flow and liquid level process control systems and components. The system uses industry-standard components mounted and plumbed in a closed-loop circuit to provide learners with the opportunity to practice manual and automatic control of a process instrumentation system by controlling the water flow rate between two tanks or the liquid level in one tank.

Amatrol’s Level and Flow Process Control Troubleshooting training system uses FaultPro, the industry’s only electronic troubleshooting system, to offer hands-on troubleshooting skills like in-circuit component testing methods and universal digital controller troubleshooting. The system also includes the industry’s best hands-on process control troubleshooting training, covering thirty-six (36) electrical faults, six (6) mechanical faults, PID controller programming errors, flow transmitter programming errors, and I/P converter calibration errors.

Amatrol’s Level and Flow Process Control Troubleshooting Learning System (T5552F) covers calibration, installation, operation, and troubleshooting for flow and liquid level process control systems and components. The process control training system uses industry-standard components mounted and plumbed in a closed-loop circuit to provide learners with the opportunity to practice manual and automatic control of a process instrumentation system by controlling the water flow rate between two tanks or the liquid level in one tank.

Amatrol’s Process Control Troubleshooting Training System uses FaultPro, the industry’s only electronic troubleshooting system, to offer hands-on troubleshooting skills like in-circuit component testing methods and universal digital controller troubleshooting. This process control training system includes the industry’s best hands-on process control troubleshooting training, covering thirty-six (36) electrical faults, six (6) mechanical faults, PID controller programming errors, flow transmitter programming errors, and I/P converter calibration errors.

Process control systems, also known as process instrumentation systems, are used in power generation, petrochemicals, manufacturing, and other industries to provide precise control of liquids and gases.

Pages

-

Item Number:373-602This economical, sectioned example showcases the device’s operating principle, internal components, and related installation concerns. Multiple cutaways unveil all internal components, which enhances classroom training in HVAC system design, maintenance, troubleshooting, and preventive/predictive maintenance.

-

Item Number:373-510This sectioned example showcases the device’s operating principle, internal components, and related installation concerns. Color coding, flow arrows, and numbered call-outs combine to make the device more informative to the inquiring student and more useful to the instructor.

-

Item Number:373-551This ACR Manual Balancing Valve Cutaway provides a full cutaway view of a balancing valve that exposes the complete internal components and operating principles. The device can be used independently using an optional tabletop mounting foot, or combined with similar devices on optional display and storage frame assemblies.

-

Item Number:373-721This ACR Oil Separator Cutaway, Float-Type provides a full cutaway view of an oil separator that exposes the complete internal components and operating principles. Color coding, flow arrows, and numbered call-outs combine to make the device more informative to the inquiring student and more useful to the instructor.

-

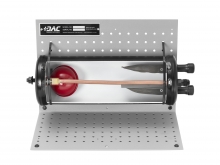

Item Number:373-722DAC Worldwide’s ACR Oil Separator Cutaway, Helical-Type is a professionally-crafted, economical teaching aid that depicts a conventional helical-type centrifugal oil separator commonly used in industrial and commercial refrigeration systems for oil entrapment and compressor crankcase replenishment.

-

Item Number:373-503This ACR Packless Diaphragm Line Valve Cutaway provides a full cutaway view of the diaphragm line valve that exposes the complete internal components and operating principles.

-

Item Number:373-502DAC Worldwide’s ACR Solenoid Valve Cutaway is a sectioned example of a commonly-encountered solenoid valve used in air conditioning and refrigeration systems with a remotely-operated maintenance-related block valve, system fluid, or gas flow control valve.

-

Item Number:373-501This ACR Steel Ball Valve Cutaway provides a full cutaway view of the compressor body that exposes the complete internal components and operating principles. Economically mounted on a formed-steel and powder-coated modular display panel, this sample panel can be mounted on a variety of optional benchtop display fixtures and storage structures.

-

Item Number:373-506This ACR Straight-Thru Pressure Relief Valve Cutaway provides a full cutaway view of the reversing valve that exposes the complete internal components and operating principles.

-

Item Number:373-701This ACR Suction Line Accumulator Cutaway provides a full cutaway view of an accumulator that exposes the complete internal components and operating principles. Color coding, flow arrows, and numbered call-outs combine to make the device more informative to the inquiring student and more useful to the instructor.