Material properties are an important consideration when evaluating additive manufacturing for advanced applications such as production runs of end-use parts. Since these products will be in service for extended periods and in varying conditions, qualifying the properties beyond published specifications is imperative.

ULTEM™ 1010 resin is a flame-retardant, high-performance thermoplastic for direct digital manufacturing and rapid prototyping. ULTEM™ 1010 resin offers good chemical resistance, high heat resistance and tensile strength, and the lowest coefficient of thermal expansion (CTE) of any FDM® thermoplastic. Its high strength-to-weight ratio and FST (flame, smoke, and toxicity) ratings make it an excellent choice for the commercial transportation industry, especially aerospace, marine, and ground vehicles.

ULTEM™ 1010 resin is offered in a certified grade (ULTEM™ 1010 resin CG), with documentation for food contact and biocompatibility compliance.

ST-130TM is a model material for sacrificial tooling that simplifies the production of hollow composite parts. Complex tools can be 3D printed and easily dissolved after curing, eliminating secondary processes like mold making and accelerating the development and production of composite structures. Engineered and tested specifically for sacrificial tooling, ST-130 withstands the heat and pressure of autoclave curing. And it 3D prints with a permeable triangle fill pattern designed to optimize build speed, conserve material and dissolve quickly.

ST-130 is available on the Fortus 450mcTM and Fortus 900mcTM 3D Printers. This solution provides increased ease of use, improved part yield, and quality – and is ideal for automotive, aerospace, and sporting goods industries.

Victrex AM 200 filament is a high-performance, low-melt PAEK (polyaryletherketone) designed specifically for additive manufacturing. It offers performance capabilities similar to PEEK and PEKK but without the challenges of 3D printing those materials. Victrex AM 200 is formulated to provide dimensional stability and optimal interlayer bonding (Z-strength).

PLA is a renewable plastic material offered as a low-cost option for fast-draft part iterations. Available on the office-friendly Stratasys F123™ Series 3D printers, PLA offers a higher stiffness than ABS, and its low melting point and HDT mean less heat and power required to print parts.

PLA works well at high speeds, specifically fastdraft mode on the Stratasys F123 Series, for quick concept verification and design development. PLA offers good tensile strength and is available in various colors, including various translucent colors. Ideal applications for PLA include fast, early concept modeling and low-cost prototyping.

ULTEM™ 9085 resin filament is a PEI (polyetherimide) thermoplastic FDM material. It features a high strength-to-weight ratio, high thermal and chemical resistance, and meets multiple aerospace and railway industry standards for flame, smoke and toxicity (FST) characteristics. Available colors are Natural, Black, Red, Jana White, White 7362, Dream Gray, Gunship Gray and Aircraft Gray.

ULTEM™ 9085 resin is a thermoplastic resin manufactured by SABIC Innovative Plastics. As you know, with all the other FDM thermoplastics the resin manufactures names and resin formulations are highly confidential.

ULTEM™ 9085 resin filament is a PEI (polyetherimide) high-performance FDM thermoplastic that is strong, lightweight, and flame retardant (UL 94-V0 rated). It features excellent heat resistance and high impact strength. It also possesses favorable flame, smoke, and toxicity (FST) characteristics.

ULTEM™ 9085 resin is available in natural and black on the F900™ and Fortus 450mc™ printers. The following six additional colors are available on the Fortus 450mc using the T16 model tip and SUP8500B™ support material: Jana White (AIC 12.36), White 7362 (AIC 12.16), Red, Aircraft Gray, Gunship Gray, and Dream Gray (AIC 2.49).

The full-color, multi-material Stratasys® J850™ TechStyle™ and J850™ Prime FabriX™ printers powered by 3DFashion™ technology boast the innovative capability of printing 3D designs directly onto fabric. With Stratasys printing materials, combinations of colors, transparency, and flexibility are possible all in one print on different textiles and flexible substrates.

The full-color, multi-material Stratasys® J850™ TechStyle™ and J850™ Prime FabriX™ printers powered by 3DFashion™ technology boast the innovative capability of printing 3D designs directly onto fabric. With Stratasys printing materials, combinations of colors, transparency, and flexibility are possible all in one print on different textiles and flexible substrates.

The following sections describe tips, guidelines, and online resources for designers to start 3D printing using Stratasys technologies and materials. With this wealth of information and your experimentation, you will gain the knowledge and skills you need to achieve outstanding results.

Guidelines and Tips

- Tips for Getting Started

- Vector Designs

- Distance Between Elements

- Element Size

- Element Height

- Size Recommendations Table

- Color Assignment

- File Type Support

- Stratasys Online Resources

Pages

-

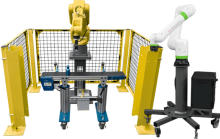

Item Number:AD2446-20The ClassMate® M cell is a complete robotic training solution designed to meet the need for advanced manufacturing training. Instructors can teach robotic concepts in the classroom and quickly move to the lab for welding practice.

-

DAC Worldwide’s selection of furniture offers a variety of solutions for creating flexible and functional training areas. Designed to work with DAC Worldwide's training systems, cutaways, models, and dissectibles, available furniture options allow you to create workstations, displays, or storage areas.

-

GrabCAD Print is a complete solution for Stratasys 3D printers. The intuitive, easy-to-use software simplifies preparing, scheduling, monitoring, and reporting print jobs. With the ability to read and understand CAD files natively, GrabCAD Print offers an efficient workflow that streamlines job management.

-

Item Number:400-PAC

DAC Worldwide’s Basic Electricity Training System Plus (400-PAC) examines basic AC and DC electrical principles. Learners will explore how electricity is used for power and control in various sectors, including industrial, commercial and residential applications. The training covers industry-relevant skills, such as installing, operating, and troubleshooting AC and DC electrical circuits in a variety of applications.

-

Safety fencing, conveyors, robot pedal stools, and CRX mobile carts