The F123CR printer series comprises the F190™CR and F370®CR composite printers, equipped with hardened components to operate with composite materials. Both systems are available with ABS-CF10 and FDM® Nylon-CF10 carbon fiber-reinforced composite materials. These materials operate with dedicated print heads for extended life. In addition, up to six engineering-grade thermoplastics are available for broader application versatility. Hands-free soluble support material enables printing highly complex parts and hands-free post-processing.

F123CR composite series printers have multiple features for ease of use and high uptime.

- GrabCAD Print™ and Insight™ software provide a simple workflow and in-depth print process control

- Fully heated build chamber enables consistent print results with multiple infills from sparse to fully dense

- Material bays located in pullout drawers allow for easy accessibility and fast changes

- Auto changeover capability on the F370CR extends print times

- Built-in camera provides visual remote print monitoring

- Power is supplied by standard wall outlets

- Printers are mounted on casters for easy mobility

Augment Machining With Composite 3D Printing

F190™CR and F370®CR FDM®

Composite Printers Supplement your fixture and part fabrication with FDM composite 3D printing to gain speed, throughput, and cost benefits.

Accessible Large-Format FDM Printing

Industrial scale printing. Simplified.

Print big without the high capital investment of exclusive, large-format printers. The Stratasys F770™ 3D printer makes printing large, complex parts affordable, reliable, and easy.

Print large or print many.

The F770 is designed with size in mind. Print one or several large parts or take advantage of the printer’s generous capacity to make multiple parts for maximum productivity.

With the longest fully heated build chamber on the market, you can print a part that is 46 inches long on the diagonal. The spacious 13 cubic-foot build envelope opens up new opportunities for manufacturing, prototyping, and production-part part applications that aren’t available with smaller printers.

There’s no need to sacrifice part complexity either. The F770 uses soluble support material, which lets you design and print your parts free from design-for-manufacturability constraints or the limitations of printers with inferior support capability. The hands-free support removal process also minimizes post-processing, increasing your productivity.

Reliable large-scale printing in a user-friendly, affordable system.

The F770™ offers one of the largest print volumes among Stratasys FDM® systems. With over 13 cubic feet of build volume and the widest build chamber (X direction) of any Stratasys FDM printer, the F770 provides the capability to build large parts or sizable assortments of smaller parts.

The F770 features industrial-grade technology for consistent, reliable performance and accurate results. Available model materials include two industry-standard thermoplastics available in three-layer thicknesses (slice heights). Soluble support material enables complex designs and hands-free post-processing.

GrabCAD Print™ software powers a streamlined workflow by printing directly from CAD files. Insight™ software is also included for more in-depth print file adjustment. The F770 is equipped with MTConnect, a manufacturing communications protocol, for factory-floor connectivity.

Built for large-scale manufacturing.

Meet demands with the Stratasys® F900™ 3D printer.

Increase throughput, reach production goals, and create large or small parts in the broadest array of FDM® materials on the market — all with the factory-ready F900 3D printer.

Designed and built for size, throughput, precision, and repeatability.

The Stratasys F900™ is the most precise and powerful FDM® system available. With the largest build size of any Fortus® system, the Stratasys F900 is designed to handle the most demanding manufacturing needs. The accuracy, repeatability, and predictability are unmatched, and the control software leverages the system’s hardware to deliver superior throughput and reliability.

The Stratasys F900 uses engineering-grade thermoplastics to build robust production parts, jigs, fixtures, factory tooling, and functional prototypes. Large parts are printed fast with slice heights up to 0.020 inches to help easily meet production demands.

The Stratasys F900 offers a streamlined workflow and easier job monitoring with an internal camera, GrabCAD Print™ software, Insight™, and MTConnect readiness. Data security, including U.S. Department of Defense STIG compliance, is provided by Stratasys ProtectAM™ technology. Standard certifications are included and reduce the workload to qualify 3D printers for a production floor.

How is the Fortus 450mc different?

Create complex geometries

- Create low-volume production parts, high-quality custom tools and functional prototypes

- The large build platform has the capability to meet industrial application needs

- Hands-free soluble support materials reduce labor while aiding in complex designs

- Easy to operate and integrate into your factory floor

Wide range of materials

- The 14 available materials support a variety of applications

- From the stiff strength of carbon fiber to the chemical resistance and ESD performance of Antero™ thermoplastics, there’s a material to meet your needs

Unparalleled consistency and precision

- Parts from the Fortus 450mc have a high degree of dimensional accuracy and precision, shown over months of tests across multiple printers with various builds

- A low variance combined with a high print success rate give you consistent, repeatable results

Industrial FDM technology with an open material ecosystem for advanced prototyping, tool production and end-use parts.

Bring the speed, agility, and design freedom of advanced additive manufacturing to your business while gaining the latest advances in FDM® technology. The Fortus 450mc™ 3D printer builds high-requirement functional prototypes, rugged manufacturing tooling, and custom production parts in its large 16 x 14 x 16 in. build envelope. Fourteen Stratasys Preferred Materials, multiple Stratasys Validated Materials, and soluble support address various applications.

OpenAM™ software lets users alter print parameters to optimize material capabilities and print results. GrabCAD Print™ and Insight™ software provide an easy CAD-to-print workflow and in-depth print processing control. MTConnect and Stratasys Software Development Kits let you integrate the Fortus 450mc into your connected factory floor. Data security, including U.S. Department of Defense STIG compliance, is provided by Stratasys ProtectAM™ technology.

PolyJet™ 3D printers empower designers, engineers, educators, and healthcare professionals to create and problem-solve without the limitations of traditional modeling methods. The power lies with PolyJet technology, curable liquid photopolymers capable of producing very fine layers for smooth surfaces, intricate details, and vivid color.

Stratasys® PolyJet technology helps bring to life ideas in virtually any spectrum of colors, and any combination of translucency, opacity, rigidity, and elasticity, while simulating several desired materials and finishes.

The versatility of PolyJet technology is based on a wide range of available material properties and a suite of 3D printers to suit varied budgets and applications. No matter the industry, PolyJet technology provides the power to hone ideas quickly and accurately.

- Help designers save 50 percent of their time. Product designers and developers can create realistic prototypes and models with full-color elements, labels, and true-to-life textures in one operation, to gain focus-group feedback before committing to full production.

- Full-color, flexible materials enable lifelike anatomical models for physician training and pre-surgical planning that lower operating room costs and improve patient outcomes.

- Educators can empower students to design, test, and discover in days, not weeks.

- Dental labs can increase productivity by making multiple models and try-ins in a single print operation to boost production capacity and fuel growth.

PolyJet technology enables you to create parts and prototypes with the best surface quality, finest details and widest range of material properties available. Eliminate design barriers and improve communication and collaboration while creating realistic prototypes to better evaluate future products; ergonomic tooling to streamline production; or specialized items like biocompatible surgical guides, among many applications.

Pages

-

Item Number:421-000DAC Worldwide’s 1-Phase Motor Control Training System with Magnetic Starter (421-000) is a motor control-related device for training in the operational principles, wiring, fault troubleshooting, and application of industrial single-phase, magnetic motor starters.

-

Item Number:420-000DAC Worldwide’s 1-Phase Motor Control Training System with Manual Starter (420-000) is a motor control-related device for training in the operational principles, wiring, fault troubleshooting, and application of industrial single-phase, manual (across the line) starters.

-

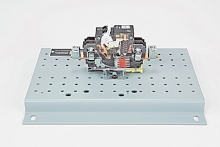

Item Number:273-907DAC Worldwide’s 100A, Single Pole Circuit Breaker Cutaway (273-907) is a detailed and professionally-crafted circuit breaker cutaway that depicts a common DIN-rail-mounted, single-phase industrial breaker. T

-

Item Number:2FG7OnRobot's 2FG7 Finger Gripper is a complete, low-cost, off-the-shelf electric parallel gripper that can be deployed on any major collaborative or light industrial robot within minutes and requires no custom engineering for installation, programming, or maintenance.

-

Item Number:2FGP20The OnRobot 2FGP20 electric gripper offers a wide stroke and customizable arms to easily handle containers that can’t be handled with traditional vacuum grippers. Like all OnRobot electric grippers, the 2FGP20 provides fast, out-of-the-box deployment with intuitive programming.

-

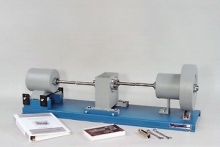

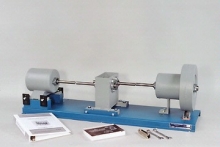

Item Number:206-000Basic mechanical maintenance skills are fundamental throughout advanced manufacturing and a wide variety of industries. For example, industrial maintenance technicians must possess essential knowledge and skills to perform shaft alignments and maintain, troubleshoot, and repair a variety of couplings.

-

Item Number:206-PACBasic mechanical maintenance skills are fundamental throughout advanced manufacturing and a wide variety of industries. For example, industrial maintenance technicians must possess essential knowledge and skills to perform shaft alignments and maintain, troubleshoot, and repair a variety of couplings.

-

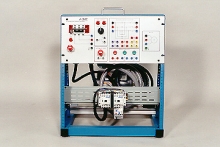

Item Number:423-000DAC Worlwide’s 3-Phase Motor Control Training System with Magnetic Starter (423-000) is a motor control-related device for training in the operational principles, wiring, fault troubleshooting, and application of industrial three-phase, reversing magnetic starters.

-

Item Number:424-000DAC Worldwide’s 3-Phase Motor Control Training System with Magnetic Starter, Low Voltage Start (424-000) is a motor control-related device for training in the operational principles, wiring, fault troubleshooting, and application of industrial three-phase, reversing magnetic starters.

-

Item Number:422-000DAC Worldwide’s 3-Phase Motor Control Training System with Manual Starter (422-000) is a task-specific, motor control-related training device that allows for skill-building in the operational principles, circuit design, wiring, fault troubleshooting, and application of industrial three-phase, manual motor starters.