Vocational Training in Prison

Employers throughout industry face a skilled worker crisis that will worsen before it gets better. Due to a worldwide skills gap and record-low unemployment rates, companies find hiring the skilled workers they desperately need increasingly challenging. At the same time, there is a large population of people that often encounter great difficulty getting hired: those with a criminal record.

Prison Training Programs can Close the Skills Gap One Second Chance at a Time

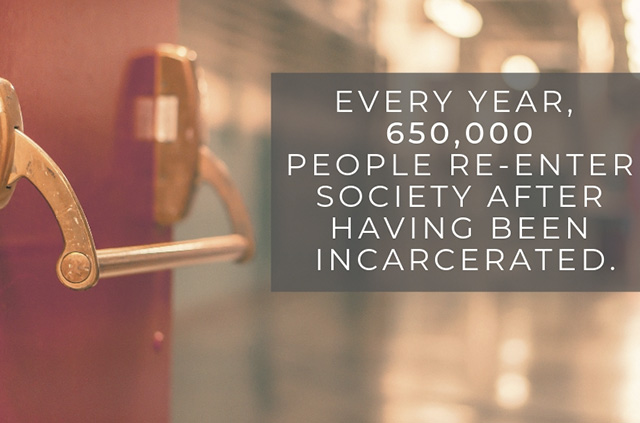

Currently, there are approximately 2.3 million Americans incarcerated. Every year, around 650,000 people re-enter society after having been incarcerated. Could this population be the solution to the skills gap?

The impact of skills training on such a huge population has tremendous potential for individuals and society. For example, a recent study revealed that participation in correctional education results in a 43% reduction in recidivism.

Focused Training is Key

While skills training holds great potential for bridging the skills gap and providing hope for a better future to those re-entering society, correctional institutions must be careful to invest in quality training programs that teach the skills industry needs. Second chances will only be successful if individuals are qualified for open jobs upon release.

Amatrol has helped correctional institutions in several states create training programs that empower individuals to move beyond their past circumstances to build a better future. Using portable training systems with locally-installed multimedia curricula, instructors can teach incarcerated individuals the skills employers need.

More Information

To engage and reach learners with a variety of learning styles, Amatrol’s Corrections-Based Training program features a robust combination of learning methods to provide a worthwhile vocational training in prison experience that includes both comprehensive theoretical knowledge and practical, hands-on skills valuable throughout industry.

More Information

To engage and reach learners with a variety of learning styles, Amatrol’s Corrections-Based Training program features a robust combination of learning methods to provide a worthwhile vocational training in prison experience that includes both comprehensive theoretical knowledge and practical, hands-on skills valuable throughout industry.

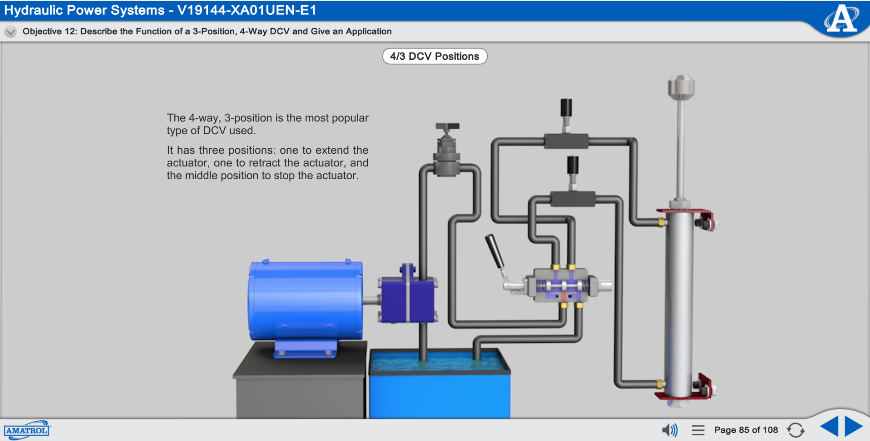

Highly-Interactive Multimedia

Amatrol’s eLearning offers flexible, self-directed technical training with comprehensive content and exceptional interactivity for practical skill development. Amatrol’s curriculum features a highly-interactive multimedia format that includes stunning 3D graphics and videos, voiceovers of all text, and interactive exercises designed to appeal to learners with different learning styles.

Amatrol’s curriculum can be installed locally via CD-ROM, so Internet access is not required.

Hands-On Skills with Real-World Equipment

Amatrol’s hands-on training systems are loaded with real-world, industrial components to enable learners to practice on the type of equipment they will encounter on the job. These portable systems have a remarkably small footprint that allows for location sharing. They can also be locked and stored when not in use. Although portable, these systems don’t sacrifice learning outcomes for flexibility. Amatrol’s portable systems offer the same type of hands-on training with comprehensive interactive multimedia curriculum available in full-size training systems.

Click on the image to learn more.

Portable Electrical Training Tools

AC/DC Electrical (990-ACDC1)

Amatrol’s Portable AC/DC Electrical Learning System (990-ACDC1) teaches the fundamentals of AC and DC electrical systems used for power and control in industrial, commercial, agricultural, and residential applications. The 990-ACDC1 offers industry-relevant skills, including operating, installing, designing, and troubleshooting basic AC and DC electrical circuits for various applications.

Relay Control (990-EC1) and Relay Control Troubleshooting (990-EC1F)

Amatrol’s Portable Electric Relay Control Training Systems cover concepts widely used in industrial, commercial, and residential applications to regulate electric motors and fluid power actuators, as well as methods used for troubleshooting problems in relay control components and systems.

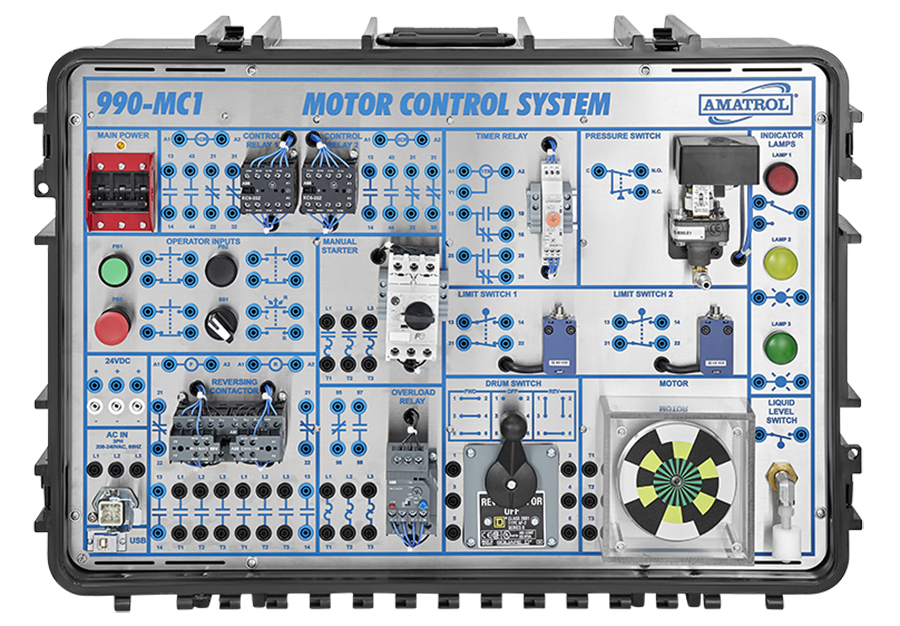

Motor Control (990-MC1) and Motor Control Troubleshooting (990-MC1F)

Amatrol’s Portable Electric Motor Control Troubleshooting Learning System (990-MC1F) features standard industry components like a 3-phase AC squirrel cage motor. It uses 3-phase AC for power and 24 VDC for control, all packed within a space-saving, portable product. These real-world motor control components will prepare learners for work opportunities in industries where electric relay control is used in applications like conveyor control and driving large utility pumps. Teach students how to read and interpret ladder diagrams. The 990-MC1F also uses FaultPro, Amatrol’s unique electronic fault insertion, to teach motor control troubleshooting skills, such as control relay, reversing contactor, limit switch, and pushbutton troubleshooting.

AC Motor Drives (990-DRV1) and AC Motor Drives Troubleshooting (990-DRV1F)

Amatrol’s Portable AC Motor Drive training (990-DRV1) features industry-standard components like a Rockwell PowerFlex 4 variable frequency AC drive (VFD) and a 3-phase AC motor used to teach how to operate an AC drive. This motor drives training system includes onboard analog and discrete input devices so learners can operate the drive in many different program applications. Optional electronic fault insertion can also be added to this system to teach valuable hands-on AC motor drive troubleshooting skills.

Portable Electronics Training Tools

Electronic Sensors (990-SN1)

Amatrol’s Portable Electronic Sensor Training System (990-SN1) teaches the operation of electronic, non-contact sensors and their applications in industry, such as sensing movement, detecting metal from non-metal, and determining speed. Packaged in a convenient, portable ABS plastic case, this system is perfect for use in small spaces or multiple locations.

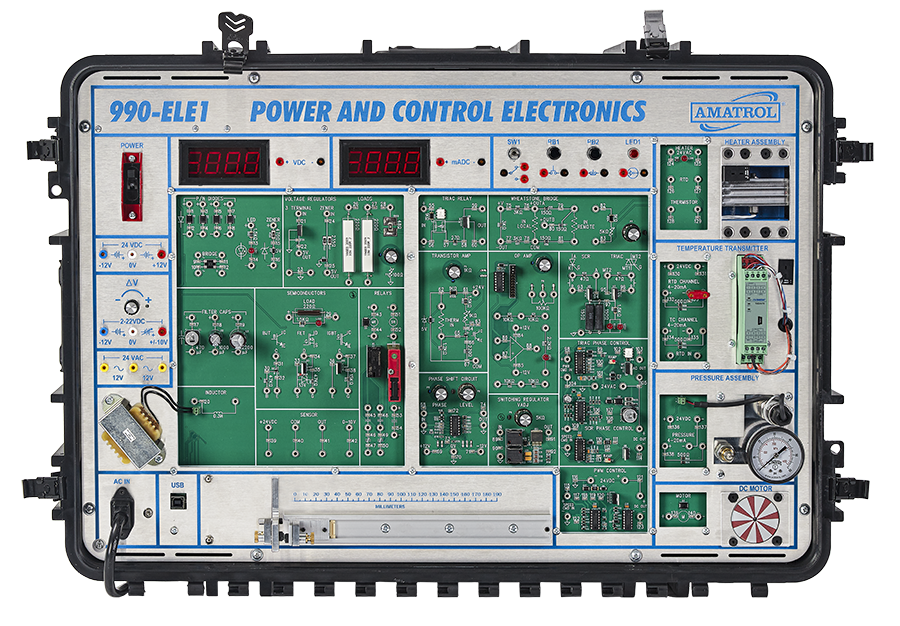

Power and Control Electronics (990-ELE1)

Amatrol’s Portable Power and Control Electronics Learning System (990-ELE1) teaches learners how to operate, adjust, and troubleshoot electronic components, circuits, and systems used in machine applications. This powerful training system allows users to explore the fundamental concepts of industrial power and control electronics, such as measuring temperature, speed, and analog signals, in a convenient, compact unit that can be easily transported to multiple locations.

Programmable Logic Controllers – Allen-Bradley (990-PAB53A/990-PAB53AF/990-PABCL1F)

Amatrol’s Portable PLC Troubleshooting Learning System - AB CompactLogix L16 (990-PAB53AF) teaches programmable logic controller (PLC) programming, operation, and applications used throughout industry. The system also utilizes FaultPro, the industry’s premier computer-based fault insertion system. FaultPro enables learners to develop key PLC troubleshooting skills, such as PLC input and output testing, software testing, and application troubleshooting.

Amatrol’s Portable PLC Troubleshooting Learning System - AB CompactLogix (990-PABCL1F) covers topics including programmable controller operation, PLC Ethernet communication, basic PLC project elements, PLC motor control, event sequencing, and more!

Programmable Logic Controllers – Siemens (990-PS712/990-PS712F)

Amatrol’s Portable PLC Troubleshooting Learning System - Siemens S71200 (990-PS712F) teaches programmable logic controller (PLC) programming, operation, and applications used throughout industry. The system also utilizes FaultPro, the industry’s premier computer-based fault insertion system. FaultPro enables learners to develop key PLC troubleshooting skills, such as PLC input and output testing, software testing, and application troubleshooting.

Portable Fluid Power Training Tools

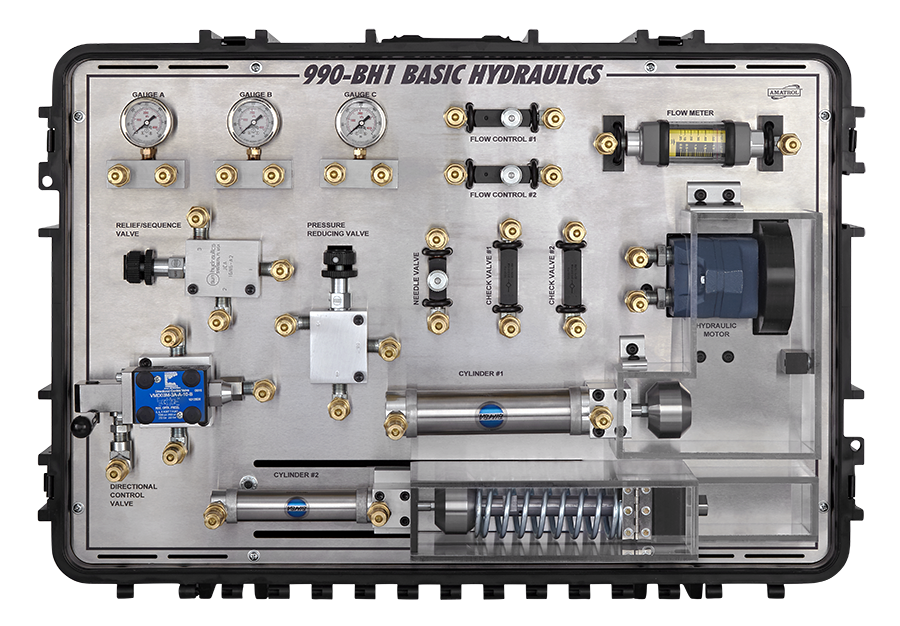

Basic Hydraulics (990-BH1)

Amatrol’s Portable Basic Hydraulics Training System (990-BH1) allows learners to gain skills by studying basic hydraulic circuits, pressure control circuits, hydraulic schematics, and sequence valves. Also, given the compact nature of the Portable Basic Hydraulics system, you can teach hydraulics in a limited space for the first time. This learning system allows learners to study and practice how to read a pressure gauge, as well as liquid level and temperature in the reservoir, connecting hydraulic circuits, operating a bi-directional hydraulic motor, converting between absolute and gauge pressure, and connecting and adjusting the pressure setting of a pressure relief valve (PRV).

Pneumatics (990-PN1)

Amatrol’s Portable Pneumatics Learning System (990-PN1) teaches basic and intermediate pneumatic concepts. Pneumatic power is a foundation of industry used in many applications across various fields, such as agriculture, pharmaceuticals, and automation. Learners will gain critical hands-on experience operating pneumatic cylinders, flow controls, directional control valves, air motors, and pressure gauges. This system requires a compressed air supply, a Hand Tool Package (41221), and a computer.

Pneumatics Troubleshooting (990-PTB1)

Amatrol’s Portable Pneumatics Troubleshooting Learning System (990-PTB1) teaches various hands-on pneumatic troubleshooting skills that are vital for those who will perform industrial maintenance, installation and troubleshooting on pneumatic systems used in real-world automation machinery, packaging equipment, pharmaceutical applications, and chemical handling tasks. The system features real-world components, such as valves, switches, and gauges — all within a convenient, durable, portable learning system.

Portable Mechanical Skills Training Tools

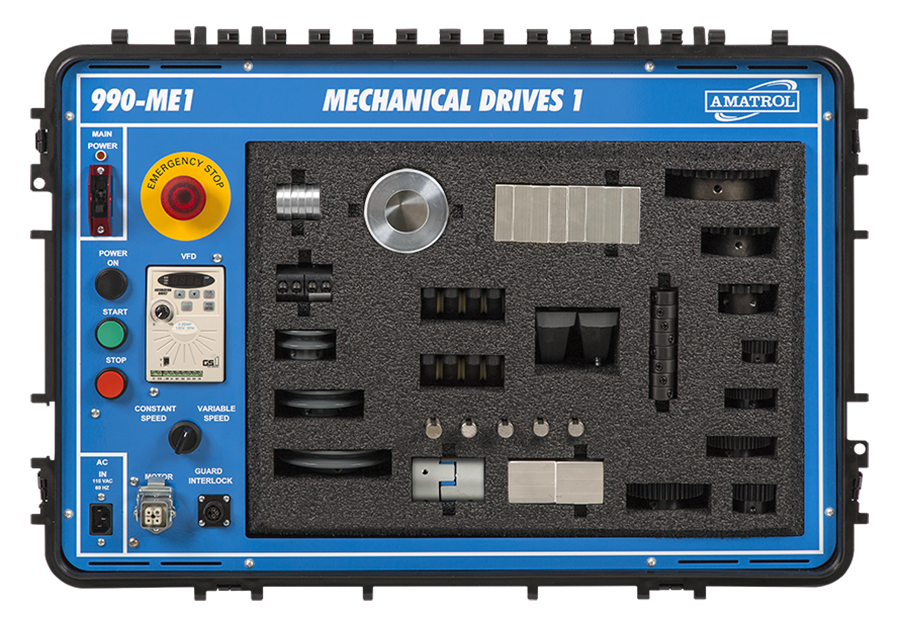

Mechanical Drives (990-ME1M)

Amatrol’s Portable Mechanical Drives 1 Learning System (990-ME1M) covers the fundamentals of mechanical transmission systems and applications, such as how to: operate, install, analyze performance, and design basic mechanical transmission systems using chains, vbelts, spur gears, bearings, and couplings. These mechanical system fundamentals can be applied to various automotive, agricultural, and power industries.

The 990-ME1M includes a tabletop mounting work surface; a drive motor; various components for belt, chain and gear drives; a digital tachometer; a mechanical load device; and an alignment package. This power transmission training system uses industrial quality components to help assure learners are better prepared for what they will encounter on the job and withstand frequent use. These components will cover major mechanical drives topics like shaft speed measurement, key fasteners, power transmission systems, belt drive concepts, chain tensioning, and gear backlash. The 990-ME1M features the ability to set up various drive systems, showing learners the effects of proper alignment and how to obtain the best efficiency.

Portable Process Control Training Tools

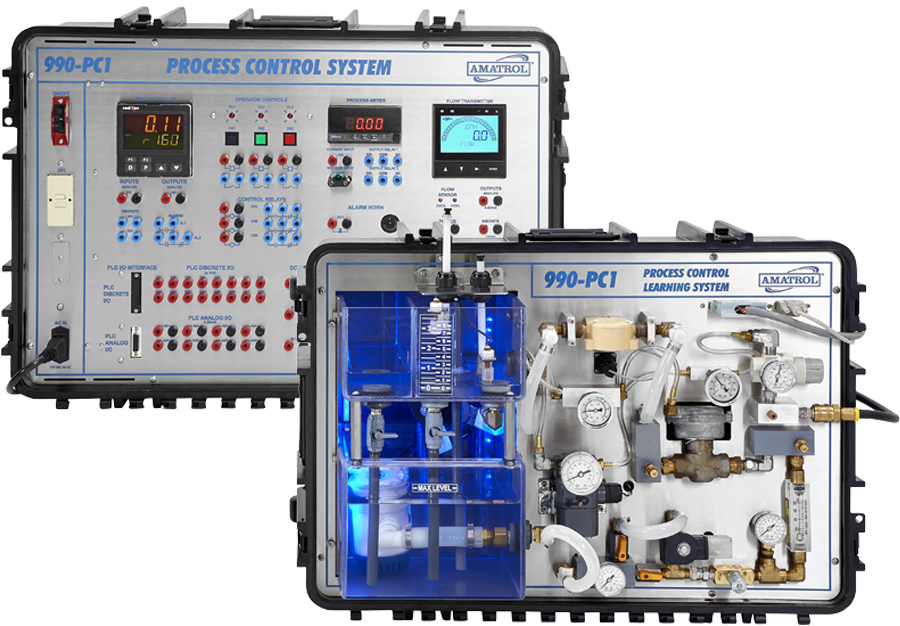

Level & Flow Process Control (990-PC1) and Level & Flow Process Control Troubleshooting (990-PC1F)

Amatrol’s Portable Process Control Troubleshooting Learning System – Level & Flow (990-PC1F) provides a skill-rich, portable troubleshooting training system for two of the most common types of process control systems, flow and liquid level. The system features eLearning curriculum and hands-on training for subjects like process control equipment safety, loop controllers, level measurement and control, control loop performance, and more.

The 990-PC1F provides vital training experience for students and professionals that will perform operation, safety, and troubleshooting on process control systems used in real-world industrial areas, including power generation, petrochemicals, food processing and manufacturing. To teach real-world skills, the training system features industry-standard valves, switches, and gauges all within a portable basic process control learning system that can be placed on a conference room table, shop floor desk, or practically anywhere when training space is limited.

Quality Assurance

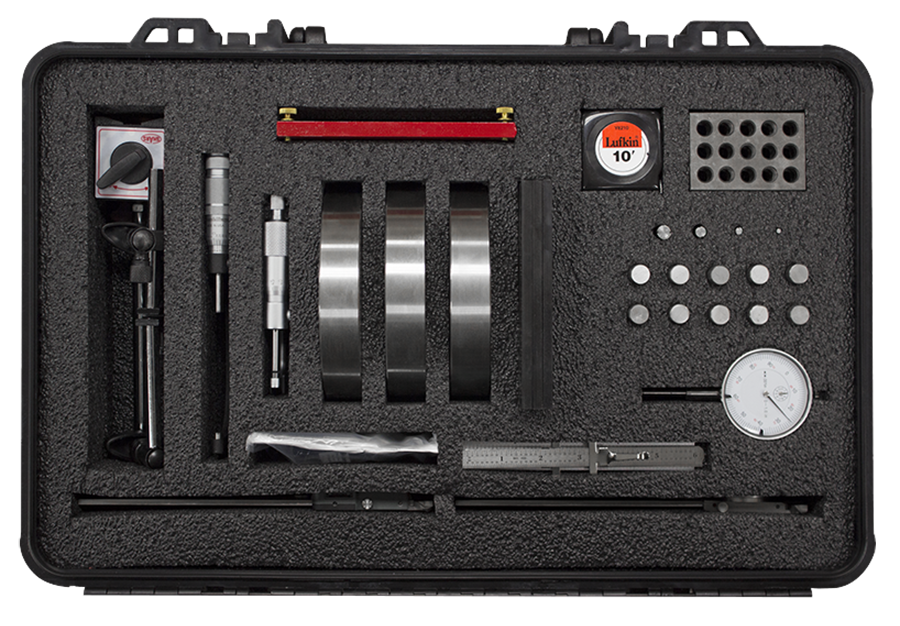

Measurement Tools (990-MES1)

Amatrol’s Portable Fundamental Measurement Tools Learning System (990-MES1) introduces the fundamental principles of measurement, including basic measurement, precision measurement, direct gauging, indirect gauging, and dimensional measurements using both the U.S. customary system as well as S.I. metric system. Understanding how to perform accurate measurements is relevant to technical careers such as quality control inspectors, machinists, manufacturing engineers, operations managers, and production technicians. The measurement training system’s compact size and the durable case also provide for safe storage when available training space must be used to teach other topics.

Precision Gauging (990-PG1)

Amatrol’s Portable Precision Gauging Learning System (990-PG1) teaches the fundamentals of basic measurement, precision measurement, direct gauging, indirect gauging, and dimensional measurements using both the U.S. customary system and the SI metric system. Measurement is a cornerstone of all technical career paths and a major part of quality assurance, helping to keep product quality high and costs low.

Industrial Certifications

Programs like CPT and CLT help inmates gain technical knowledge, skills, and industry credentials to increase the likelihood of post-incarceration employment. Due to restrictions on inmate access to the internet, MSSC has made accommodations to allow prisons to access the CPT Amatrol material offline. This program allows inmates to utilize state-of-the-art, interactive curricula based on MSSC standards.

Heavy Equipment Simulators

Alaska Department of Corrections' Goose Creek Correctional Center (GCCC) opened in July 2012 and houses over 1,500 inmates. With over thirty newly established vocational programs, GCCC's mission emphasizes rehabilitation and re-entry into society.

GCCC's vocational programs are growing. The programs combined "NCCER Heavy Equipment Simulator Level 1 - 3" which uses National Center for Construction Education Research (NCCER) curriculum guidelines for Heavy Equipment Operations (HEO), and Simlog's Personal Simulators for practical skills training.

Welding Simulators

Bridge the Classroom to the Real World with Welding Training Systems

Help welders hone skills faster and for less money, and prepare the next generation of welding professionals to exceed demands for enhanced quality and competency with Lincoln Electric’s VRTEX® and REALWELD® trainers.