Amatrol’s FaultPro computer-based fault insertion software is the industry’s only electronic troubleshooting training system. FaultPro allows instructors to instantly set and tailor faults to test a student’s weaknesses and turn them into strengths.

Manufacturing & Engineering

Our learning programs develop job-ready skills that have been proven time and again. Take a look at how we can help you be successful!

Our learning programs develop job-ready skills that have been proven time and again. Take a look at how we can help you be successful!

Colleges are challenged to offer courses whenever students are available – and frequently, wherever they are available. Students want courses that are available on campus as well as from home while also providing strong hands-on skills for the technology demands facing them. Meeting these demands is no small task.

Amatrol has learning programs that allow colleges to excel in this demanding environment. We offer a full range of learning systems, both in a traditional equipment lab setting as well as in a virtual lab, that meet and exceed students' expectations.

-

-

Amatrol’s Smart Factory Tabletop Mechatronics system provides a full mechatronics line in a small space and is a great way to introduce Industry 4.0 to students.

-

Item Number:APTARC50Welding programs that want to teach the latest technologies will add robotic welding to their program offering. This easy-to-program collaborative robot...

-

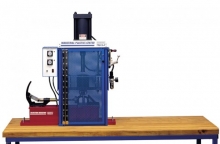

Item Number:BH-85Each Basic Hydraulics training system features standard industrial grade components. This attention to quality gives students experience they would normally only get on-the-job by helping them recognize industrial components and how to troubleshoot them more effectively. Components included with Basic Hydraulics are pre-mounted on circuit panels with silk-screened labels next to each, which facilitates ease of use and identification.

-

Item Number:85-BPAmatrol’s Basic Pneumatics training system (85-BP) introduces pneumatic principles through a combination of Amatrol’s top-flight multimedia curriculum with hands-on industrial pneumatic skill-building. Topics covered in this learning system include single-acting cylinder circuits, pressure vs. cylinder force, and flow control valves, while the panels can be used to practice skills such as connecting and operating a needle valve to control actuator speed.

-

Item Number:85-EHThe Electro-Hydraulics training system includes an electrical control panel with relay control components and an electrical valve module with solenoid-operated hydraulic directional control valves and electrical/electronic sensors. These components will be used to study a variety of topics including electrical control systems, basic control devices, power devices, control relays, sequencing control, timer control, pressure control applications, and circuit applications.

-

Item Number:LMT-300LMT-300 CNC Mill-Turn is a cutting-edge aluminum cutting machine

-

Item Number:96-PLS1TThe injection molding trainer includes a temperature control system, 4 oz. shot material feed system with electro-pneumatic control, dual heater system, barrel and nozzle, safety enclosure, heavy-duty workstation, 8-ton clamping system, mold offset plates, set of injection starter molds, interactive curriculum for both theory and lab, and a teacher’s assessment guide.

-

Item Number:96-PLS2The 96-PLS2 includes a clamping system, extrusion die for use with blow molding, pneumatic blow system, starter mold for blow molding, extrusion die, interactive curriculum for both theory and lab, and a teacher’s assessment guide. Students will learn skills such as creating a plastics part using a blow molding operation, troubleshooting blow molds, designing a blow mold using CAD/CAM, creating a blow mold using a CNC machine, creating a plastics part using an extrusion operation, and testing an extrusion for uniform diameter.

-

Item Number:LMV-F400 RLAn excellent teaching machine with an all in one production center. This top of the line Milling Machine includes an attached FANUC LR Mate 200iD Robot arm. With this machine, educators have everything they will need to teach students both Robot programming and CNC machining.