Each Advanced Manufacturing topic incorporates the skill development needed for modern industry. From operation to complex troubleshooting, Amatrol’s learning systems deliver job-ready skills.

Process Control

Process control is a versatile and vital part of major industries, including power generation; petrochemicals; food processing and bottling; chemical manufacturing; biotechnology; pharmaceuticals; and refineries.

Because of the wide application of this key component, Amatrol has developed the largest and most in-depth offering of industrial process control training options available. Amatrol offers four major process control trainers, each covering a different process control application: level and flow, temperature, analytical, and pressure. Amatrol also offers a variety of training options for related process control applications such as HART communication protocol, Foundation Fieldbus, and SCADA.

-

-

Item Number:603-000Hands-on exercises include industry-relevant process control skills, such as: setting and adjusting pressure switches; installation and calibration of an electronic flow measurement channel; and determining a temperature, pressure, level, and flow process’ operation characteristics.

-

Item Number:120-BPT | 120-CFCD | 120-CPT | 120-IPTInstrumentation and Process Control Training aids include a Basic Process Trainer, Flow and Level Control Trainer, and an Instrumentation Process Trainer.

-

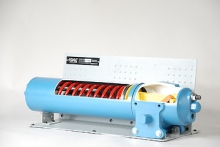

Item Number:T5552FAmatrol’s Level and Flow Process Control Troubleshooting Learning System (T5552F) covers calibration, installation, operation, and troubleshooting for flow and liquid level process control systems.

-

Item Number:990-PC1Amatrol’s Portable Process Control Troubleshooting Learning System – Level & Flow (990-PC1F) provides a skill-rich, portable troubleshooting training system for two of the most common types of process control systems, flow and liquid level.

-

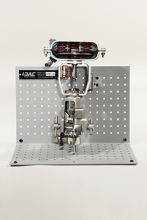

Item Number:273-510DAC's Rack and Pinion Pneumatic Actuator Cutaway (273-510) is a detailed valve actuator cutaway that depicts a rack and pinion-type pneumatic valve actuator commonly used as a closure device on industrial 1/4-turn valves.

-

Item Number:273-410SSDAC’s Sanitary Diaphragm Valve Cutaway, Stainless (273-410SS) is a specialized, sectioned valve and actuator assembly that unveils the complete working mechanism of a representative diaphragm-actuated, stainless steel control valve used in sanitary service.

-

Item Number:273-520DAC's Scotch-Yoke Actuator Cutaway (273-520) is a detailed valve actuator cutaway that depicts a common Scotch yoke-type valve actuator often used as a closure device on industrial 1/4-turn valves.

-

Item Number:272-715DAC Worldwide's Dissectible Sight Flow Indicator Sample (272-715) allows for close visual inspection of a common in-line flow indicator to better understand its function, design, and operation.

-

Item Number:T5553Amatrol’s Temperature Process Control Learning System (T5553) demonstrates how to install, calibrate, operate, adjust, and tune thermal process control systems in a wide variety of industrial applications, including food processing, chemical manufacturing, and biotechnology.