Annually, thousands of individuals in the US suffer injuries caused by electricity. At times, workers may come across equipment and circuits that are powered or pose a risk of being energized during their tasks. Without adequate precautions, an arc flash incident can occur.

An arc flash, also known as a flashover, is an electrical discharge or explosion arising from a connection through the air to the ground or another voltage phase within an electrical setup. For instance, this happens when a wire comes into contact with an earthed system. Working near or within electrical panels and systems heightens the risk of exposure to an arc flash, necessitating extreme safety measures.

Learning Objectives

The primary goal of this course is to teach workers safe work procedures while performing work activities around electrical areas. The user will learn:

- The proper locking out and tagging out electrical equipment

- How to properly do a Live – Dead – Live check

- Practices that can eliminate or minimize electrical hazards

- The proper use of electrical test equipment

- Electrical fundamentals

- Properly managing arc flash risks

- Electrical safety Personal Protective Equipment (PPE)

The simulation is ideal for personnel working in and around hazardous electrical areas.

Equipped with even greater accuracy, a larger field of view, and the same compact form as its predecessor, Artec 3D's fully automated desktop 3D scanner Micro II allows users to make professional reverse engineering and quality inspection effortless. Activated by a simple click of a button, this 3D scanner for small objects provides a stringent 5-micron accuracy to create highly precise, full-color 3D models of industrial parts, dental, and jewelry. Or, combine scans with photogrammetry data to take hyper-realism to a whole new level, right on your desktop.

Seeking innovative training solutions for the oil and gas sector? Dive into Hard Hat VR, a revolutionary immersive training platform crafted specifically for the high-stakes realm of oil and gas. Step away from outdated methods and embrace Virtual Reality tailored to enhance safety and efficiency in your industry!

Why Hard Hat VR for Oil & Gas?

- Realistic Oilfield Scenarios: Experience training in lifelike oil rigs and refineries without real-world risks.

- Industry-Tailored Interactivity: Engage in hands-on, industry-relevant training for lasting impact.

- Cost-Effective Solutions: Slash training expenses and minimize operational interruptions.

- Enhanced Safety Protocols: Prepare your workforce for real hazards within a controlled VR environment.

Who Benefits?

- Oil and Gas Companies

- HSE (Health, Safety, and Environment) Professionals

- Technical and Vocational Institutes

Maximize Your Gains

- Heightened Training Efficiency

- Elevated Safety Standards on the Field

- Enhanced Knowledge Retention Among Employees

The Smart Automation Certification Alliance (SACA) recently hosted an exclusive Process Control Technical Work Group meeting at Endress+Hauser headquarters in Greenwood, Indiana. The meeting brought together experts in the process control and instrumentation industry to help validate certification standards for process control in areas such as process control systems, process control troubleshooting, and smart process instrumentation.

In this video, SACA Executive Director Jim Wall and Endress+Hauser Director of Workforce Development Nicole Otte discuss the importance of industry experts providing input on the skills and competencies needed for today’s smart manufacturing workforce. Collaboration with industry experts is essential to create nationally-recognized, occupation-driven certifications that will ensure that future workers have the skills employers need most.

According to Wall, “The whole goal of having the standards and certifications program is to help schools and colleges and other training providers develop and expand programs that include these new technologies, so that we get more people with these skills into the workforce.”

Ladder safety is a key aspect of fall prevention. According to the CDC, 81% of fall injuries, which is the leading source of fatalities among construction site workers, involve the use of ladders. As such, it’s important to remember and follow ladder safety best practices. Ladder Training isn’t considered a necessity by law, but the importance is often overlooked. The HSE recommends that anyone using ladders needs to be competent and carrying out officially certified training is one way to do this. Teaching the basics of ladder health and safety can help prevent potential injuries and inform others on how to identify if a ladder is a potential risk.

Learning Objectives

The primary goal of this course is to teach workers safe work procedures to follow when using ladders in a work environment. The user will learn:

- To identify hazards associated with ladder use

- How to select the correct ladder for the job

- How to inspect a ladder for defects

- How to practice proper safety procedures

- To see the consequences of improper actions

The Ladder Safety simulation is ideal for employees or supervisors who work in or around work environments that utilize ladders.

Oakland Community College (OCC), situated in Auburn Hills, MI, stands as one of FANUC America's esteemed 1,500 partner institutions. At OCC, a specialized robotics and automated systems technology program equips students for roles in the realm of industrial automation. The automation lab at OCC houses an extensive array of FANUC robots renowned worldwide for their application in material handling, welding, palletizing, and machine tending across various industries. Graduates from OCC, having acquired certifications or degrees, emerge primed for careers in industries employing robotics and automation technology.

This video spotlights OCC's steadfast dedication to nurturing individuals into adept professionals in advanced automation, paving the way for prosperous career trajectories. Through firsthand accounts from multiple students, viewers gain insights into their educational journey and future aspirations. The central message underscores the demand from employers seeking individuals capable of bridging the skills gap. OCC's program not only supplies skilled workers to meet industry demands but also assists its graduates in securing fulfilling and rewarding career paths.

Explore Amatrol's state-of-the-art tabletop mechatronics trainer featuring a FANUC Cobot, ideal for comprehensive education in mechatronics and automation. Immerse yourself in the realm of smart factories and technical advancement as we showcase the prowess of this advanced trainer. Contact us to delve into the exhilarating world of mechatronics.

Elevate HVACR Education with Amatrol's Cutting-Edge Training Solutions

Explore Amatrol's comprehensive suite of HVACR training systems, meticulously designed to immerse learners in industrial, commercial, and residential heating and cooling technologies. Our curriculum covers traditional air conditioning methods alongside diverse topics such as insulation, lighting, ceiling fans, and cutting-edge renewable energy systems like geothermal applications.

One of our flagship offerings includes a specialized steam training system, essential for grasping fundamental concepts and honing skills utilized in diverse industries such as paper mills, power generation companies, and even aboard nuclear submarines. Amatrol's suite of thermal products seamlessly integrates into various pivotal programs, including HVACR, Power and Energy, STEM initiatives, and Industrial Maintenance training.

Diverse Applications, In-Depth Learning

Amatrol's HVACR training products not only cater to foundational learning but also enable students to delve into advanced applications and emerging technologies within the realm of heating, ventilation, air conditioning, and refrigeration. With a focus on hands-on learning, our systems empower learners to master critical skills essential for success in today's dynamic industrial landscape. Whether pursuing careers in commercial HVACR, residential installations, or exploring renewable energy systems, Amatrol's training solutions provide a robust platform for skill development, aligning with the demands of evolving industries.

Experience an innovative approach to HVACR education with Amatrol – where theory meets practical application to forge competent, industry-ready professionals.

In this video, Mike Idle provides an overview of Amatrol’s Commercial Refrigeration Learning System (T7400). This trainer teaches users how to operate, control, and troubleshoot commercial refrigeration systems like those used in commercial air conditioning, refrigerated display cases, walk-in coolers and freezers, and more. This system will prepare future commercial refrigeration technicians to handle various real on-the-job issues efficiently.

The Commercial Refrigeration Learning System includes several real-world components that allow users to practice hands-on skills. Some of these components include a semi-hermetic compressor, evaporators, a condenser, expansion and solenoid valves, electric and air defrost, adjustable airflow fans, an oil separator, and more.

FaultPro, Amatrol’s premier computer-based fault-insertion system, is also included. By utilizing FaultPro and the included multimedia curriculum, users can practice troubleshooting 35 different faults and perform multiple hands-on skills. Some skills covered include taking airflow measurements, configuring a smart controller for single-zone operation, adjusting the pressure settings on a dual pressure control device, and operating a multi-evaporator commercial refrigeration system.

Experience the power of Advanced Manufacturing education as students at a Bluegrass Community & Technical College embark on a hands-on journey using Amatrol equipment. Join us to explore the world of skills training in manufacturing as these students develop their expertise on campus. Get inspired and gain valuable insights into the future of post-secondary education.

At BCTC's Georgetown campus, the Advanced Manufacturing Center mirrors a genuine work environment, prioritizing experiential learning over conventional classrooms. Housing specialized labs for industrial maintenance technology, advanced manufacturing, computerized machining, integrated engineering technology, and electrical engineering, the campus caters to around 300 students each semester. Captivated by the layout and cutting-edge facilities, students seamlessly translate classroom knowledge into real-world manufacturing scenarios.

Pages

-

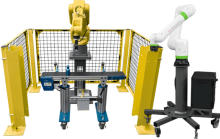

Item Number:AD2446-20The ClassMate® M cell is a complete robotic training solution designed to meet the need for advanced manufacturing training. Instructors can teach robotic concepts in the classroom and quickly move to the lab for welding practice.

-

DAC Worldwide’s selection of furniture offers a variety of solutions for creating flexible and functional training areas. Designed to work with DAC Worldwide's training systems, cutaways, models, and dissectibles, available furniture options allow you to create workstations, displays, or storage areas.

-

GrabCAD Print is a complete solution for Stratasys 3D printers. The intuitive, easy-to-use software simplifies preparing, scheduling, monitoring, and reporting print jobs. With the ability to read and understand CAD files natively, GrabCAD Print offers an efficient workflow that streamlines job management.

-

Item Number:400-PAC

DAC Worldwide’s Basic Electricity Training System Plus (400-PAC) examines basic AC and DC electrical principles. Learners will explore how electricity is used for power and control in various sectors, including industrial, commercial and residential applications. The training covers industry-relevant skills, such as installing, operating, and troubleshooting AC and DC electrical circuits in a variety of applications.

-

Safety fencing, conveyors, robot pedal stools, and CRX mobile carts