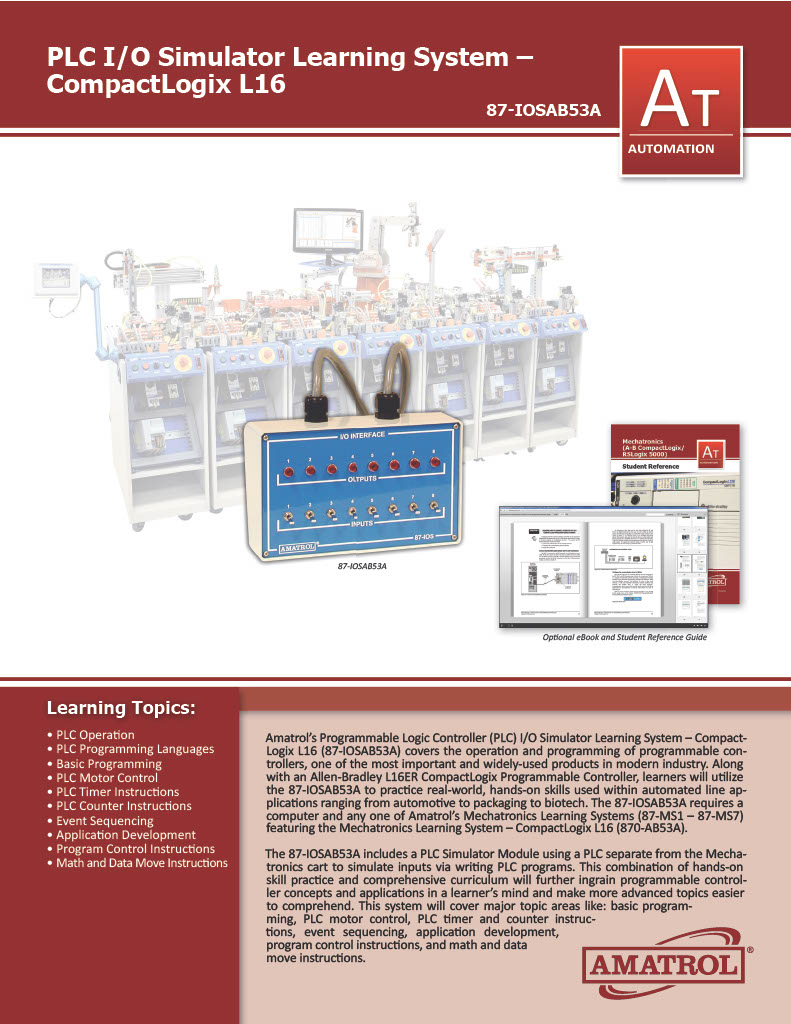

Amatrol’s Programmable Logic Controller PLC I/O Simulator Learning System – CompactLogix L16 (87-IOSAB53A) covers the operation and programming of programmable controllers, one of the most important and widely-used products in modern industry. Along with an Allen-Bradley L16ER CompactLogix Programmable Controller, learners will utilize the 87-IOSAB53A to practice real-world, hands-on skills used within automated line applications ranging from automotive to packaging to biotech. The 87-IOSAB53A requires a computer and any one of Amatrol’s Mechatronics Learning Systems (87-MS1 – 87-MS7) featuring the Mechatronics Learning System – CompactLogix L16 (870-AB53A).

The 87-IOSAB53A includes a PLC Simulator Module using a PLC separate from the Mechatronics cart to simulate inputs via writing PLC programs. This combination of hands-on skill practice and comprehensive curriculum will further ingrain programmable controller concepts and applications in a learner’s mind and make more advanced topics easier to comprehend. This system will cover major topic areas like: basic programming, PLC motor control, PLC timer and counter instructions, event sequencing, application development, program control instructions, and math and data move instructions.

Amatrol’s PLC Learning System – Siemens S7-1500 (87-IOSS715) provides an input/output simulator that allows learners to test PLC programs by providing manual input and output indicators that connect to a Siemens S7-1500 PLC input/output. This Siemens PLC program simulation system adds to Amatrol’s Mechatronics Learning System – Siemens S7-1500 (870-S715) and covers vital PLC training topics like PLC operation, programming, motor control, event sequencing, timer instructions, and counter instructions. The knowledge and skills covered by this PLC training system are extremely valuable for advanced manufacturing career opportunities like industrial maintenance technicians.

In addition to the PLC simulator module, the PLC training system for the Siemens S7-1500 PLC includes interactive multimedia curriculum, an instructor’s guide, an installation guide, and a student reference guide. Amatrol’s world-class multimedia training courses provide real-world technical knowledge that covers theoretical concepts and reinforces hands-on skills. Within this PLC online eLearning curriculum, learners will study PLC communications and program execution, PLC program editing and documentation, seal-in program logic, safety interlocks, multiple actuator sequencing, on-delay and off -delay timers, and count up and count down instructions.

Computer-Based Fault Insertion Software

The Mechatronics Manual Fault Insertion Training Module (87-MF1) adds troubleshooting capabilities to Amatrol’s 870 series Mechatronics system. Mechatronics systems are used in almost every industry including manufacturing, material processing, and packaging. The ability to troubleshoot these systems quickly is essential in today’s competitive markets and the Mechatronics Manual Fault Insertion training can enable your learners to acquire these skills.

The 87-MF1 Module provides the ability to insert 12 faults to a mechatronics station. Add a module to one or all of your mechatronics stations to give learners a real-world troubleshooting experience. Sensors, switches, and PLC faults are just a few of the available faults. To insert a fault, the instructor simply replaces a Standard Circuit Plug in the module with a Fault Plug. Once inserted, the Fault Plug is unidentifiable from the Standard Circuit Plug. This ensures that the learner cannot look at the fault module and see which fault has been inserted, avoiding the common problem of using toggle switches to turn faults on and off.

If you want a more sophisticated fault insertion method that provides computer-based electronic fault insertion and performance tracking, ask about Amatrol’s electronic fault insertion system, FaultPro, the only electronic fault insertion system that automates tracking the learner’s troubleshooting experience.

Amatrol’s Basic Fluid Power Learning System – Single Surface Bench (850-C1) teaches the fundamentals of two bedrocks of industry: hydraulic and pneumatic power. This fluid power training system includes three panels on its work surface and can store up to four additional panels under the work surface for expanded hydraulic and pneumatic training.

The basic fluid power training system includes a controls technology bench with a hydraulic power supply and Amatrol’s basic pneumatics and hydraulics systems. These systems feature industrial-quality components to prepare learners for what they will encounter on the job. Major topics covered by the system’s multimedia curriculum include hydraulic and pneumatic power systems, basic hydraulic and pneumatic circuits, principles of pneumatic and hydraulic pressure and flow, and hydraulic and pneumatic speed control.

Amatrol’s 87-MS1, Mechatronics Pick and Place Feeding, is station 1 of the 870 Mechatronics Learning System. The 87-MS1 station is a small mechatronics system in itself with multiple, integrated technologies that can be used stand-alone or in combination with other stations. Industrial safety and operation are emphasized on all Amatrol mechatronic stations.

Interfacing, Programming, Sequencing & Operation

Amatrol’s 87-MS2, Gauging, is station 2 of the 870 Mechatronics Learning System. The 87-MS2 station is a small mechatronics system in itself with multiple, integrated technologies that can be used stand-alone or in combination with other stations. Industrial safety and operation are emphasized on all Amatrol mechatronic stations.

Index Tables, Stepper Motors, Homing Sensors

Amatrol’s 87-MS3, Mechatronics Orientation-Processing Station, is station 3 of the 870 Mechatronics Learning System. The Mechatronics orientation training station is a small Mechatronics system in itself with multiple, integrated technologies that can be used stand-alone or in combination with other stations. Industrial safety and operation are emphasized on all Amatrol Mechatronic stations.

Mechatronics Sorting and Buffering

Amatrol’s Mechatronics Sorting-Buffering Learning System (87-MS4) is training mobile workstation 4 of the 870 Mechatronics Learning System. The 87-MS4 station is a small Mechatronics system in itself with multiple, integrated technologies that can be used stand-alone or in combination with other stations. In efforts to protect workers and machines, industrial safety and operation are emphasized on all Amatrol Mechatronic stations.

The Sorting-Buffering training station teaches interfacing, problem solving, programming, sequencing and operation for sorting, queuing, flat belt conveyors, photoelectric sensors, and inductive sensors. This station performs the role of sorting parts by material type in the process of assembling a working industrial control valve.

The 87-MS4 is a mobile workstation with slotted work surface that contains an operator station, belt conveyor module, part sorting module, buffer module, proximity sensing module, parts set, a pneumatic distribution module as well as an electrical distribution module, an electro-pneumatic valve manifold, and a digital I/O interface module.

Mechatronics Robotic Assembly

Amatrol’s 87-MS5-P2, Servo Robotic Assembly – Pegasus II, is station 5 of the 870 Mechatronics Learning System. The 87-MS5-P2 station is a small Mechatronics system in itself with multiple, integrated technologies that can be used stand-alone or in combination with other stations. Industrial safety and operation are emphasized on all Amatrol Mechatronic stations. The Servo Robotic Assembly station trains students for pick and place assembly, and teaches interfacing, problem solving, programming, sequencing and operation for servo robotics, gravity feeders, pneumatic screw feeders, and part insertion. This station performs the role of assembling a working industrial directional control valve using a combination of servo robotic and pick and place technologies.

The 87-MS5-P2 has two mobile training workstations with slotted work surfaces that contain an operator station, Pegasus II servo robot with teach pendant, spool insertion module, screw feed module, spring/knob feed module, screw/knob engagement module, assembly shuttle module, parts presentation module, finished parts storage module, parts set, a pneumatic distribution module as well as an electrical distribution module, an electro-pneumatic valve manifold, and a digital I/O interface module.

Interfacing, Programming & Sequencing

Amatrol’s 87-MS6, Torque Assembly, is mobile training station 6 of the 870 Mechatronics Learning System. The 87-MS6 station is a small Mechatronics system in itself with multiple, integrated technologies that can be used stand-alone or in combination with other training work stations. Industrial safety and operation are emphasized on all Amatrol Mechatronic stations.

Pages

-

Item Number:J55The Stratasys J55 Prime 3D printer introduces full color, high fidelity with tactile, functional, and sensory capabilities - making the efficiency and quality of PolyJet Technology more affordable and office-friendly than ever.

-

Item Number:J850 DAPThe Stratasys J850™ Digital Anatomy™ 3D Printer combines materials and software to create 3D medical models of human anatomy that mimic bone and tissue with realism you can see and feel.

-

Item Number:T7081Understanding HVAC/R, geothermal, refrigeration, and steam systems requires a good hold on the basics. With Amatrol's T7081 Applied Thermal Science Trainer, you can provide the hands-on training your students or employees need.

-

Item Number:APTARC50Welding programs that want to teach the latest technologies will add robotic welding to their program offering. This easy-to-program collaborative robot...

-

BOFA’s Advantage 350 fume extraction and filtration system effectively removes potentially harmful fumes and particulates created during the laser marking process. By maintaining a dust-free operating area, the system helps to protect valuable equipment, maintain a higher quality mark, and reduce the number of rejects and contaminants.

The quiet and compact Advantage 350 is ideal for use in light-duty laser marking applications, including schools, sign making workshops and small-scale industrial environments.

-

Our largest high-volume fume extractor with unique Gullwing filter access design making filter exchange quick, safe and easy.

BOFA’s AD 4000 laser fume extraction unit combines large filter capacity with high airflows. This combination makes the AD 4000 ideal for large laser engravers, laser cutters as well as multiple laser coding installations.

Easily accessible filters are accommodated by the uniquely styled gas spring assisted ‘Gull Winged’ doors, which allow for maximum space and ease when changing filters.

-

BOFA’s AD 1000 iQ high end laser extraction system combines extremely large filter capacity with high airflow and pressure rates, making it the ideal choice for heavy-duty applications that generate large amounts of particulate and gaseous organic compounds.

Performance has now been further enhanced with the inclusion of several new features including BOFA’s new iQ Operating System, making the new AD 1000 iQ one of the most advanced system available.

-

The AD Access combines economic ownership with performance to match the small laser user. A three-stage filter condition indicator is included as a standard feature, together with three stage filtration: DeepPleat pre-filter, HEPA and chemical section.

-

The Advantage Base 1 Oracle has been designed so that a number of manufacturer’s laser engravers can sit on top of the extractor, effectively doubling it up as a workstation.

All the Base units in the range have the option of an onboard compressor for a compact installation. BOFA’s ‘Easi-Seal’ filter location makes filter change easy, quick and safe.

The revolutionary Auto-Voltage Sensing Turbine automatically self-adjusts to run on any voltage worldwide, whilst the Reverse Flow filter technology enhances filter performance and ensures longer filter life.

-

The Laser Companion 'Ride On' range has been designed so that a number of manufacturer's laser engravers can sit on top of the extractor, effectively doubling it up as a workstation.

The Advantage Base 2 Oracle has been designed so that a number of laser engravers can sit on top of the extractor, effectively doubling it up as a workstation.

All the Base units in the range have the option of an onboard compressor for a compact installation. BOFA’s Easi-Glide filter location mechanism makes filter changes easy, quick and safe.